The company that pioneered the concrete rebar-tying robot TyBot has unveiled a new innovation for rebar crews. It’s called IronBot, and it’s the world’s first lifting, carrying and placing concrete rebar robot, says creator Advanced Construction Robotics.

ACR announced at ConExpo this month that IronBot can place up to 5,000 pounds of reinforced-steel bar per hour, relieving workers of the backbreaking labor. It can lay the rebar in 5,000-pound bundles in horizontal or longitudinal positions.

Combining IronBot with TyBot – what ACR calls the “Bot Bundle” – the robots can cut work time in half, the company says. And they can work day or night, rain or shine.

The Bot Bundle was used to complete a pilot project in February for an expanded St. Lucie West Boulevard Bridge over I-95 in St. Lucie County, Florida. A new eastbound bridge is being constructed beside the existing bridge, which will eventually serve as two westbound lanes.

The rebar-installation subcontractor on the project, Shelby Erectors Inc. worked with IronBot and TyBot to reduce the time on the rebar job from 14 to seven days, ACR reports. Check out Advanced Construction Robotics’ video below to see IronBot and TyBot in action:

Shelby Erectors has been using TyBot for about two years. The St. Lucie bridge was ACR’s first project in testing IronBot.

“We were impressed that we could slash our rebar installation schedule in half,” says Jack Nix, Shelby Erectors chief operating officer. “We are actively looking for new projects to incorporate the Bot Bundle in our operations."

On the bridge project, IronBot placed 147,032 pounds of rebar over 6.5 production shifts, while TyBot completed 58,068 ties, according to ACR. IronBot requires a “robot supervisor” to walk beside the IronBot with a remote control and perform onsite maintenance.

IronBot can work on bridge decks ranging from 10 to 117 feet wide and rides on an existing screed rail. It can place bars 9 to 60 feet long and can be set up on site in four to eight hours. The robot automates rebar placement based on the job’s spacing requirements. It does not need any pre-programming, pre-mapping, calibration or BIM input, according to ACR.

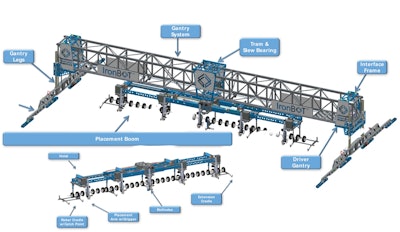

The anatomy of Advanced Construction Robotics' IronBotAdvanced Construction Robotics

The anatomy of Advanced Construction Robotics' IronBotAdvanced Construction Robotics

IronBot is manually positioned by the robot supervisor on the jobsite using the remote control. The robot starts at the first position for rebar to be placed, and the robot supervisor enters the desired bar spacing.

“Once placement starts, IronBot tracks its position through local odometry (data from motion sensors) to place subsequent bars,” says ACR’s website. “Cameras see once the bar is in the catch point (fed by the rollindex) and automatically grabs the bar and releases at the correct height. Once the bar is placed, IronBot automatically moves forward to the next placement location and repeats until stopped by Robot Supervisor.”

IronBot can also place multiple bars in a single location or skip locations, depending on the job specifications.

Two contractors have become the first to be certified by ACR to use the Bot Bundle as subcontractors: Bayman Construction and Advantage Steel & Construction. They earned the certification in the “Certified Innovators” program after dedicated crews underwent hands-on training using the devices. They can provide the robotic rebar installation service in these states: Florida, Maryland, North Carolina, New York, Ohio, Pennsylvania, South Carolina, Tennessee, Texas, Virginia and West Virginia.

"I am so excited to see our initial prediction of cutting schedules by at least 50% come to fruition on IronBot’s maiden voyage,” says Danielle Proctor, CEO of Advanced Construction Robotics. "This robotic revolution provides innovative construction firms the ability to become game-changers by adopting and putting their ‘modern crew’ to work.”

IronBot on under-construction St. Lucie bridge, the first pilot project for the robot that lifts, carries and places rebar.Advanced Construction Robotics

IronBot on under-construction St. Lucie bridge, the first pilot project for the robot that lifts, carries and places rebar.Advanced Construction Robotics