Jeff Johnson has mixed many batches of asphalt during his 29 years at heavy highway construction company S.T. Wooten, but in June, he scored a first when some of his mixes caught the attention of the scientific community.

That month his name was included on a study published in a science journal that examined the use of disposable surgical masks to reduce rutting on asphalt roads. The study determined that the polypropylene in the masks, which have become a common sight during the Covid-19 pandemic, could be melted down to a binder for hot mix asphalt. It also showed promise that it could reduce road rutting, as well as serve as a potential way to keep some of the billions of masks from ending up as litter, in landfills where they will take an estimated 450 years to decompose, and in oceans and other waterways.

So how did Johnson get involved?

For about 10 years, he has led tours of Wooten’s asphalt plant in Wilson, North Carolina, for students of George Wang, chairman of East Carolina University’s Department of Construction Management. Johnson is the plant’s quality control manager.

One day, Wang was walking on ECU’s campus when he saw a discarded mask on the ground and started thinking about recycling the billions of face covers that have become a symbol of the two-year pandemic and an environmental problem.

He called Johnson to see if Wooten would be interested in creating hot mix asphalt samples using the masks.

“It was new for us,” Johnson says.

The company does recycle asphalt roof shingles and uses recycled road millings in its asphalt, but this was its first time recycling plastic.

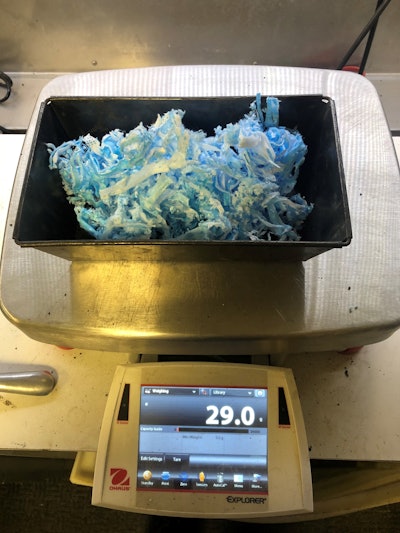

For the mix, the masks were run through a paper shredder. The mask shreddings were weighed in increasing increments of 0.25% of the total weight of each sample. The seven samples, or “pills,” weighed 3,000 to 3,700 grams each and were 75 millimeters, or about 3 inches, high. The hot mix asphalt samples contained one of the following percentages of face mask remains: 0%, 0.25%, 0.50%, 0.75%, 1.0%, 1.25% or 1.5%.

The aggregate was heated up to 300 degrees. The shredded masks were placed on top and melted. The ingredients were mixed together. The liquified polypropylene acted as a binding agent. The samples were then taken to the North Carolina Department of Transportation in Raleigh where they were tested on the agency’s Asphalt Pavement Analyzer for rutting depth.

The results were promising.

“They were all within specs,” Johnson says of the test samples. “Actually, I think it helped out.

“I think it gives it more strength. It helps the bonding process … and the results kind of show that.”

The results were published June 20 in the journal Science of the Total Environment under the title “Use of Covid-19 single-use face masks to improve the rutting resistance of asphalt pavement.”

The lead author is Wang, and among the other researchers listed as contributors is Johnson.

“Well, I had no idea it would go that far,” he says and chuckles. “I was just trying to help Dr. Wang out.”

The study reached this conclusion:

“This study shows that the mixes with different SFM (single-use face mask) percentages had good resistance against rutting, while the result was outstanding for the mix containing 1.5% SFM.”

Rutting depths were reduced from 3 millimeters to a “very low” 0.93 millimeters, according to the study. NCDOT allows maximum rut depth in mix designs of 4.5 to 11.5 millimeters, depending on the type of mix.

The masks also “increased the stiffness of the mixes and improved the adhesion between the aggregates.”

Much more study needs to be conducted before the remnants of used Covid masks will make it into asphalt roads. Wang hopes to continue the research.

Johnson observed some challenges with the mask mix that will need to be addressed.

For one, a paper shredder was used to cut up the masks, but to be effective, the masks will need to be shredded into much finer particles. Another challenge would be coming up with a way to meter the shredded masks uniformly into the mix.

But he’s also ready to assist in further research.

“There's definitely a need to recycle our natural resources and stuff that is not natural, stuff that we made,” he says. “There's definitely a need for that. And I'm willing to help.”