A new framework design could make bridges more resistant to earthquakes while speeding construction, Science Daily reports.

The design, which aims to improve the performance of the columns and beams that support bridges, is based on research findings that will be presented in Alaska later this month at a summit focusing on earthquakes.

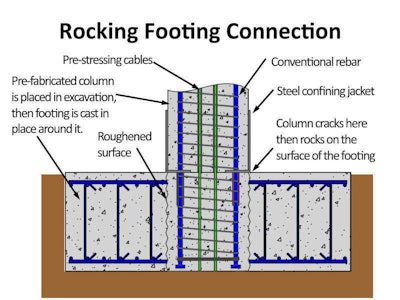

A new design for prefabricated bridges could help them stand up to earthquakes. The design features high-strength steel cables, rebar and steel tubes. (Photo credit: University of Washington, Seattle/NEES)

A new design for prefabricated bridges could help them stand up to earthquakes. The design features high-strength steel cables, rebar and steel tubes. (Photo credit: University of Washington, Seattle/NEES)Researchers are examining a type of pre-fabricated structure that uses pre-tensioned columns, which would allow portions of the bridge to be constructed off-site while still providing the durability needed to stand up to an earthquake.

John Stanton, a professor in the Department of Civil and Environmental Engineering at the University of Washington, Seattle, developed the design’s concept.

“A good analogy is to think of a series of a child’s wooden building blocks, each with a hole through it,” he said in the Science Daily report. “Stack them on top of one another, put a rubber band through the central hole, stretch it tight and anchor it at each end. The rubber band keeps the blocks squeezed together. Now stand the assembly of blocks up on its end and you have a pre-tensioned column. If the bottom of the column is attached to a foundation block, you can push the top sideways, as would an earthquake, but the rubber band just snaps the column back upright when you let go.”

Stanton noted that high-strength steel cables would act as the rubber bands on a full-size bridge. Those cables, along with rebar, would be integrated into the bridge’s concrete during pre-fabrication.

This technology is not new to the construction industry. According to Science Daily, it has been used for building construction since the 1990s.

In addition to the cables and rebar, the design features short steel tubes that confine the concrete to prevent it from crushing under the high stress brought on by an earthquake.

A team of graduate assistants have already tested the design on a small scale, but they plan to test it on a complete bridge at a facility at the University of Nevada this month.