According to OSHA, caught-in hazards collectively are one of the four deadliest dangers found on a construction site. Although it seems like common sense to never place yourself between a piece of heavy equipment and an immovable object, when you’re concentrating on the job at hand sometimes you find yourself in unexpected danger. Here are some tips to prevent becoming a victim of caught-in/between accidents.

1. Hazard recognition

Your company’s OSHA competent person will have performed a site analysis for each job. Familiarize yourself with the hazards – and potential hazards – you’ll encounter on the site. Ask what personal protection systems will be needed for the job and make sure you have the necessary personal protective equipment (PPE). Recognize that as the work progresses, the hazards may change, and new hazards may materialize.

2. Equipment safety

Never use a piece of equipment unless all of the guards are in position and properly adjusted. Pay special attention that rotating or moving parts are properly guarded. Always realize you can get caught in machinery by belts, pulleys, gears, rotating shafts and other moving parts. Also, ensure you’re wearing the correct PPE for the job, and avoid loose clothing and other items that can be caught in machinery.

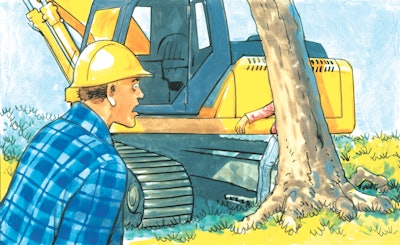

3. Maintain distance

If you’re not the one operating a piece of equipment, stay away from it. If you’re too close to a machine, you could get pinned between the equipment and a stationary object such as a wall, barrier or other piece of equipment. Also, stay out of the swing radius of equipment; the operator may not be able to see you. If you must approach a piece of equipment, make eye contact with the operator and use a clear hand signal that you are approaching his machine.

4. Respect barricades

Areas unsafe for pedestrian traffic will be barricaded. Make sure the barricade is properly maintained, and avoid walking within the designated area. If the equipment is in a stationary position, such as a crane could be, caution tape may be used to warn nearby workers of the crane’s swing area. Flagging personnel may also be used to identify unsafe areas. If at any time you see a barrier that has fallen, is loose or is damaged, report it as quickly as possible so it can be repaired or replaced.

5. Monitor material movement

When materials are moved overhead from one location to another, the possibility arises of a load being placed on a part of the body, or of the body being caught between the load and a wall or structure. Always work at a safe distance from the load and ensure you don’t come between the load and its final resting place.