Proper tractor ballasting isn’t just for large tillage tractors. The simple truth is proper tractor ballasting is just as important on smaller utility tractors as it is on your largest tractors. Correct ballast is important to the machine’s stability and performance, and can help improve safety when using front-end loaders, using three-point mounted equipment or operating on sloped ground.

“Too much weight can cause a tractor to feel sluggish, can increase soil compaction, reduce fuel efficiency and result in premature drivetrain wear,” says Scott Sloan, ag product manager, Titan and Goodyear Farm tires. “And too little weight can result in tire slippage, reduced fuel efficiency and can cause premature tire wear.”

And to be sure, proper ballasting can be complex. Fortunately, there are many resources available online or from your tire dealer to help with ballasting tractors.

“The end game is trying to minimize tire slippage when you head to the field,” Sloan says. ”Between inflation pressure and ballasting you will have your tractor performing at its most efficient. Most manufacturers shoot for slip in the 8 to 15 percent range. Anything over that is extremely noticeable and not very efficient. Most growers I deal with do prefer to be running in the 3 to 9 percent range.”

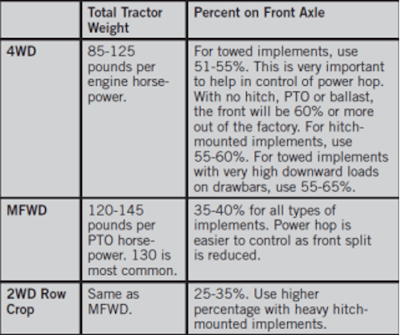

Recommended guidelines for proper ballasting and weight distributionsTitan Tire

Recommended guidelines for proper ballasting and weight distributionsTitan Tire

Sloan says a good guide for a four-wheel-drive tractor is to have anywhere between 85 to 125 lb. per rated horsepower. For instance, a 4WD tractor rated at 500 hp should be in the 50,000 to 55,000 lb. total weight with 55 to 60 percent on the front and 40 to 45 percent on the rear. “Not only is the total machine weight important, the distribution of that weight is just as critical,” Sloan says.

It also is important for each producer to understand the factors involved with proper ballasting and their objectives. “One producer may be satisfied with a little more slip and a lighter machine, while the other wants to pin all the power to the ground,” Sloan says. “Trial and error with an understanding of these factors and patience to experiment with different ballast packages with will result in a well optimized tractor performing at the highest efficiency.”

Tire choice impacts stability as well.

Producers may associate tractor ballasting with power hop and road lope. But ballasting isn’t the only solution to these issues. “Tire choice can dramatically decrease the occurrence of these issues as well. For instance, Low Sidewall Technology (LSW) tires are designed with a larger rim diameter than standard farm tires, but with the same outside diameter of the tire,” Sloan says. “The larger wheel and shorter sidewall provides greater stability and helps dampen the effects of road lope and power hop before they spiral out of control.”

In high draw-bar applications such as planting, power hop can sometimes get so severe that it impacts the seed getting into the ground.

“The bouncing effect of road lope can inhibit you from running the machine at full speed down the road from field to field — which can have a huge impact on your productivity if you do a fair amount of roading,” Sloan says. LSW tires help eliminate these issues. LSW tires also are designed to carry the weight load at up to 40 percent lower inflation pressures than standard tires, which can dramatically reduce ground-bearing pressure and therefore soil compaction.