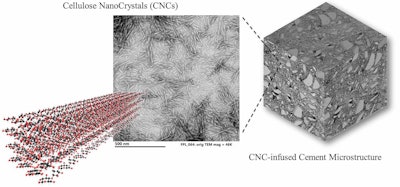

Purdue University researchers are testing whether they can make a stronger bridge by using concrete infused with microscopic nanocrystals from wood. Photo courtesy of Purdue University.

Purdue University researchers are testing whether they can make a stronger bridge by using concrete infused with microscopic nanocrystals from wood. Photo courtesy of Purdue University.Researchers at Purdue University have found a way to make concrete stronger by infusing it with cellulose nanocrystals, byproducts generated from wood, and will test it on a bridge that will be built in California this spring, according to a news release from the Purdue Research Foundation. At press time, the exact bridge where the cellulose-infused concrete will be used had not yet been determined.

“Simply getting out there where people can actually drive on it, I think, is a huge step, because you can’t just say it’s a lab curiosity at that point. It has real-world implications,” said Jeffrey Youngblood, a Purdue professor of materials engineering, in the news release.

Stronger concrete could lead to thinner and lighter concrete structures, with a possible decrease in the amount of carbon dioxide released into the atmosphere while making cement. The cellulose nanocrystal is approximately 100 nanometers long and 5 nanometers wide, and makes the concrete stronger through a chemical reaction that increases the hydration of the cement particles, making the concrete stronger.

“The strength of concrete scales with the degree of hydration,” Youngblood explains in the news release. “So the more hydrated it is, the stronger it is. So you’d think if you add more water it would be stronger. The problem is, water adds pores that make it weaker. But cellulose nanocrystals enhance hydration with less water, making the concrete stronger.”

Youngblood said another benefit is that the cellulose-infused concrete sets faster, which means the concrete cures much faster when using forms to make bridges.

The cost of using cellulose nanocrystals may be offset by being able to use less cement. The exact cost of using cellulose nanocrystals hasn’t been determined, but how widely they are used will have an impact. However, researchers said if only a small percentage of all the concrete produced used cellulose nanocrystals, it would still have a big impact.

The bridge project in California is a partnership between Purdue, Oregon State University, P3Nano (a public-private partnership designed to support commercializing cellulosic nanomaterial), and others. P3Nano has been involved in the trials and is the sponsor of the bridge project to demonstrate full-scale applications of cellulose nanocrystals in bridges and flat slabs.

Research on the uses of cellulose began 10 years ago in collaboration with Robert Moon, a researcher from the U.S. Forest Service Forest Products Laboratory, who was based at Purdue at the time. The Forest Service was looking to find a use for diseased, damaged, and small-diameter logs found in forests.

Nano-Green Biorefineries Inc. has a license agreement with the Purdue Research Foundation Office of Technology Commercialization to commercialize the technology.