[imagebrowser id=181]

Caterpillar announced the successors to its K Series small wheel loaders during a special pre-show briefing at World of Concrete Monday night with the 926M, 930M and 938M.

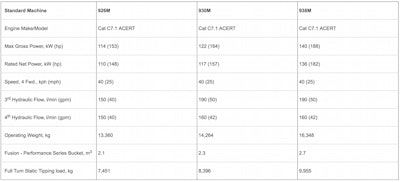

The new M Series loaders are all available with a set of new options and are powered by a Cat C7.1 ACERT Tier 4 Final engine that the company says offers “hybrid-type” fuel savings.

Plus, each of the machines boast power increases, a top speed of 25 miles per hour and higher tip loads over their K Series predecessors.

Inside the cab of the 938M.

Inside the cab of the 938M.Cat has replaced the 924K with the new 926M, a 29,453-pound machine with 153 horsepower. The 930M weighs in at 31,446 pounds and has 164 hp while the 938M is 36,041 pounds and has 188 hp. As the K Series machines, the M Series loaders will still be available in the Aggregate Handler, Waste Handler and Forest Handler segment-specific packages.

The C7.1 ACERT engine reduces emissions but does not disrupt work cycles thanks to a clean emissions module that uses a fit-for-life diesel particulate filter (DPF) and a selective catalytic reduction system which only requires the addition of diesel exhaust fluid (DEF).

The engine is paired with a hydrostatic drive system that offers three powertrain modes: traditional Hystat mode with aggressive engine braking; Torque Converter mode, allowing the machines to free wheel down hills and around grades; and Ice mode. Cat says the Torque Converter mode is the factory default setting as it can save an additional 5 percent in fuel in load and carry applications.

But those big “hybrid-type” fuel savings come thanks to the machines’ improved Standard power modes. In Standard mode, the machines offer the same power as their K Series predecessors in ranges 1-3, but a new “Power-by-Range” logic boosts power in range 4 for higher speed on uphill grades. This tweak lowers engine speed in standard mode by 200 rpm, reducing fuel consumption by 5 percent in Cat’s testing of composite-work cycles and up to 10 percent “in specific applications, such as roading, long load-and-carry applications, and snow clearing.”

930M

930MThe lower engine speed also makes the cabs on the M Series machines significantly quieter. However, Power mode boosts engine speed to 1,800 rpm when max power is needed.

Speaking of the cab, Cat is now offering a larger redesigned secondary display for the M Series loaders that allows operators to customize controls to their liking while offering up a wealth of information: operator profiles, application profiles, service-mode and preventive maintenance alerts, independent flow adjustment for third and fourth hydraulic functions, directional-shift response, ride-control activation speed, automatic-lubrication intervals, bucket- float activation, feather-catch mode, rack snubbing, multiple camera inputs, Perfect Parallelism, diesel exhaust fluid (DEF) level, and remaining time until fuel fill.

The machines feature the same electro-hydraulic contorls and Generation II Optimized Z-bar loader linkage as their K Series predecessors. Cat says the controls do offer a new feature called Perfect Parallelism, which provides level lift within ± 2 degrees accuracy using sensors in the linkage. The feature allows for better site lines to fork tips and comes in handy in material handling applications.

A bevy of new options are available for the machines including an LED light package that includes front and rear LED auxiliary work lights, engine-bay LED lights to illuminate routine service points and lighting to illuminate the fuel area. A new radar-based Object Detection System is also available for the loaders, providing visual and audible alarms to warn the operator of objects close to the rear of the machine.

Cat also announced that it has made its Product Link telematics service standard on the M Series machines. Purchase of one of the machines also includes a three-year subscription to the VisionLink web interface for viewing machine status and diagnostics.