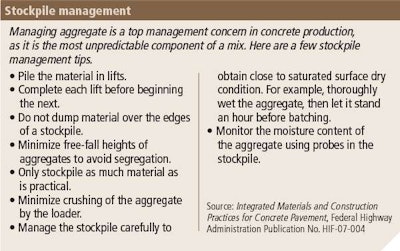

While cement and water are critical and need to be monitored, the aggregate poses the biggest challenge for concrete pavement contractors, according to Leif Wathne, executive vice president of the American Concrete Pavement Association.

“A lot of the issues with plant operation is aggregate handling, so the loader operator becomes a key feature of a concrete mix operation,” he says. “If your loader operator knows what he’s doing, you’re going to be much more likely to have a consistent mix that performs the way it’s designed, and is proportioned properly.”

Moisture content is a big issue in this process, Wathne says. “A lot of plants will put sprinklers on, but how they manage that is going to control whether that moisture is super wet on top. Just because they put sprinklers on top doesn’t mean it’s going to be at the right moisture content.”

But well-graded aggregate is perhaps the top issue, he says, stressing the effect of this factor on performance. (In fact, the asphalt industry has also been focused on this, because the consequences of poor aggregate gradation in asphalt pavement are more obvious and can cause immediate problems.)

“In concrete, it may not be inherently obvious what the performance issues are. Even placement issues are associated with poor aggregate gradation,” Wathne says.

Plants need to have an assortment of aggregate gradations, including coarse, intermediate, and fine. “I think getting well-graded aggregates is the most cost effective way for a concrete paver to consistently deliver and place high quality concrete pavement,” Wathne says.

Admixtures

The concrete paving industry has been criticized for its seemingly increasing reliance on performance-enhancing admixtures.

“Along with these various admixtures, when we also use supplementary cementitious materials like fly ashes or slags, sometimes incompatibilities can develop that cause the concrete to react in unexpected ways,” he says. And some admixtures are sensitive to extreme ambient temperatures or too-wet aggregate.

“You then have outcomes you would never anticipate,” Wathne says. “It’s just a more complicated system. In the past, we didn’t have these tools available to us, so we ended up with mixtures that performed fine, but they were probably not optimized.”

Performance troubleshooting

In addition to the aggregate gradation, contractors must also look at the design of the mix and the proportioning. The design establishes the concrete’s strength, intended purpose, and environment.

This means contractors must scrutinize what they are designing, the proportions of the mix, and other specifications to determine if they can expect it to perform properly.

“A lot of it has to do with uniformity as well,” Wathne says. “You’re paving day in day out and it’s a tough environment out there because the weather and material changes.” Contractors have to constantly adjust for all these variables in their paving operation so that a uniform, smooth product comes out of the paver every day.