Most contractors understand you don’t waste daylight. But by the time the sun breaks over the mountains of central West Virginia, Dwaine Doss has already put in hours of work. When your customers are the top dogs drilling for gas in the Marcellus Shale, starting time is typically 4:30 a.m. Quitting time? Don’t ask.

Long before anybody had ever heard of the Marcellus Shale, Doss started running equipment early, as a teenager. He worked in the coal mines, did pipeline work, eventually starting his own company.

“I’ve known Dwaine for 25 plus years,” says Dave Huffman, Cleveland

Skill was one thing Doss had from the outset. But to get where he is today also took a lot of foresight, tremendously long hours, a great relationship with his dealer and the ability to recruit the best operators and foreman in the region.

One day it became apparent to Doss that energy companies were quietly buying up leases and mineral rights in central West Virginia. Something was afoot, something that later became known as the Marcellus Shale. Doss sensed correctly, that it would be huge. And he wanted in. The shale gas revolution, which began in Western Pennsylvania and West Virginia, offered him the chance to transform his company from a small earthmoving and sitework business to a major significant player in the energy field.

“I wanted to be the best, and to do that I knew I had to grow,” Doss says. So he sat down with his Caterpillar salesman and began what turned into a series of discussions about the equipment he would need to reach his goals. Dwaine says that this partnership was one of the keys to helping him take his company to the next level.

“I could not have done it, I could not have come this far,had it not been for Cat and my Cat salesperson,” he says.

What Doss needed and Cat provided, was a deep-dive analysis of the type of equipment required to go after this market and how to deploy a much larger and more expensive fleet in a way that would be profitable. He also needed to learn how to structure his business to be able to work and succeed in this high-speed, high stakes business. To meet the demands of the drilling companies, Doss needed a big fleet and the ability to attack jobs with the speed and efficiency demanded of investors who sink millions of dollars into each and every one of these deep wells and fracking operations.

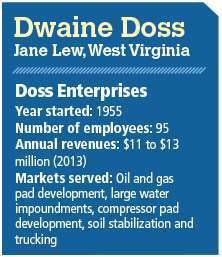

Today Doss Enterprises works almost exclusively for the energy and drilling companies, building containment ponds, drilling pads, access roads, and compressor pads.

No excuses

Shale gas, fracking wells … this is the big leagues. Excuses or machine downtime won’t cut it. The when the drilling rigs arrive, they come barreling in on dozens of oversize 18-wheelers. These trucks are often dragged to the top of mountains using big dozers because trucks and truck engines don’t have the traction or torque to pull such heavy loads up steep grades. And when the rigs get to the top of the mountain, the drilling pads, the acres of generators and, the big containment ponds better be ready.

“I’ve known Dwaine for seven or eight years now,” says Shawn Bennett, Antero Resources, “and every company I’ve worked for I’ve asked Dwaine to come in and help. He’s one of those contractors you can put on a site and you don’t have to worry about him. He always takes care of his equipment. It’s always in good working order. There are never any issues with anything breaking down. There isn’t anything I’ve asked Dwaine to do that he hasn’t done in a satisfying manner. He’s top notch on safety, he’s honest, he has a quality product and he’s on time – the most important things.”

“He’s the kind of guy you can sit down with and talk and whatever Dwaine tells you, you can take to the bank,” says Bob Johns, World Wide Equipment. “Dwaine always does what he tells you he’s going to do and the customers love him because he is very efficient at what he does.”

Doss Enterprises is also an active member of ISNetworld. This is a company that collects and verifies safety, procurement, quality and regulatory information from contractors. Being a member requires contractors have a world-class safety record and program that is auditable and available for oil companies to review. If you want to work in the oil field services business, ISNetworld is a requirement.

Hiring the best

None of this success would have been possible without good people. Doss relies on a highly experienced workforce of loyal supervisors, managers, operators and mechanics. Many of them have been with him for a long time.

Out in the field, when he introduces his guys, it’s always with words of high praise, saying things like: “This guy is a genius. You’re meeting the master. You can’t find a better dozer operator than this guy.” He also says he’s got two of the best welders and mechanics in the state working for him. What they all share in common with Dwaine is the ability to get demanding tasks done on time, regardless of how many hours it takes.

In season, the crews work as much as 70 hours a week. Many make close to union scale wages. Dwayne says his greatest motivator in all of this is the fact that he can provide jobs for these men, that he can put money in their pockets, food on the tables and enable them to raise families.

Despite the intense schedule, Doss will not ask anybody to work on Sundays. He is a firm believer in the Sabbath. He will take volunteers but he understands the value of a day of rest. And Doss is not afraid to wear his faith on his sleeve. When asked about his success in life he always answers: “The most important thing is that I’m a Christian and believe in Jesus Christ as my Lord and Savior.”

Doss gets to work at 4:30 every morning, he says, and oftentimes works until 7 at night. He has never taken a vacation. He doesn’t see the point. He puts everything he makes back into the business, only drawing out enough of a salary to pay his household expenses.

High expectations

Dwayne says he is a demanding boss, but fair. To work for him you have to deliver, excuses won’t cut it. The energy/drilling companies he contracts to expect it. Deadlines have to be met. There is way too much money to be made for delays and overruns to be tolerated.

“I’ve been around a lot of his employees and he doesn’t have a big turnover,” says Johns. “So that tells me he takes very good care of them. I know some of his employees personally and some of them left other companies to work for Dwaine.”

“Dwaine’s biggest asset is his ability to work and his desire to be successful,” says Huffman. “Six or seven days a week he’s in the office.”

As far as entry level laborers go, Dwayne says he can and sometimes will take on a young man with limited skills if he has the right work ethic. Even those that have some training often learn to do things different from what Dwayne and his supervisors need, so they have to retrain them, anyway. But it’s the hunger, the desire to make things happen, the fire in the belly that he looks for above everything else.

Equipment matters

Doss was quick to adopt GPS machine control when it became available several years ago. “He has really embraced technology and has two or three Trimble systems on his dozers and excavators,” Huffman says. “Most of his equipment is new and he wants to be sure to only move the amount of dirt that needs to be moved.”

And with a big fleet and a demanding schedule, Doss makes every effort to make sure the yellow iron is well taken care of. “He is an excellent equipment manager,” says Johns. “He is very meticulous with all of his equipment and Dwaine is the kind of guy who won’t go out and buy just anything. He can get more out of any piece of equipment than anyone I’ve ever seen.”