As you delve deeper into the second-generation, family-owned excavation contractor in New Paltz, New York, you realize that the philosophy behind their gleaming jobsite presence guides every facet of the company – from the boots-on-the-ground laborer to the top leadership.

It all boils down to one simple statement:

“Our goal is to be above industry standards for everything.”

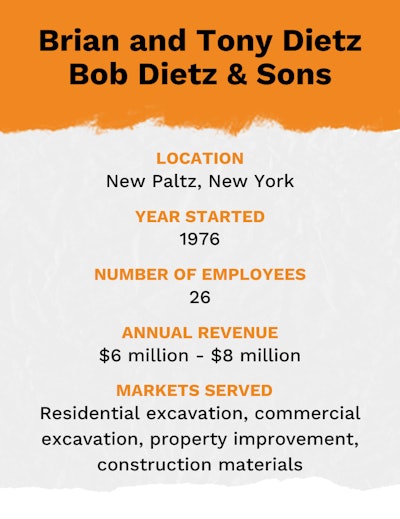

Brian and Tony Dietz have carried forward that guiding principle learned from their father, Bob Dietz, who started the company in 1976. It not only means having equipment in spotless condition but how they treat employees, their use of technology, their jobsite efficiency and safety, their customer relations and improving their leadership skills. It also means going outside their comfort zone, especially in attracting and retaining young employees by allowing four-day work weeks and making a point to help train the industry’s next generation.

Though their efforts have not been easy, they have resulted in them becoming nationwide social media influencers and experiencing exponential annual growth of 25% for the past 10 years. Revenues are expected to hit another record in 2024, topping $12 million.

For that reason and more, Bob Dietz & Sons is Equipment World’s 2024 Contractor of the Year.

Taking Ownership

Bob Dietz & Sons embraces the challenges of difficult projects.Bob Dietz & Sons

Bob Dietz & Sons embraces the challenges of difficult projects.Bob Dietz & Sons

When milk prices crashed in the 1970s, Bob Dietz turned to excavation work to earn a living, performing mostly residential site work. As toddlers, his sons were operating equipment, and when they graduated high school, Brian and Tony went right into the family business.

“At a pretty young age, he allowed us to unofficially have ownership of the business,” Brian says.

“I think that taught us some valuable lessons and, honestly, kept us interested in the business,” adds Tony.

In time, the brothers expanded the company’s horizons, growing with the unique opportunities and challenges of their region. They are based in the Hudson Valley, about 80 miles from Manhattan. Their projects center on the desires of some of the country’s wealthiest people who view the area as a retreat from the city.

One upcoming project involves tearing down a $10 million mansion, deemed to be in the “wrong spot,” for a $60 million compound.

They have performed work for the first new premium-brand distillery in the state, on a 400-acre property. Exclusive golf resorts with cabins, hotel and restaurants are also popular and are part of the company’s repertoire. The latest trend is glamping – as in “glamorous camping” – for which Dietz performs the site work and utility installation for resorts where people spend lots of money to stay in luxury yurts amid beautiful Catskills scenery.

One of their specialties is tackling difficult projects, such as a 104-townhome complex that required 76 days of blasting to carve out a rock hill.

“It was right next to a school,” says Brian. “We had 15-minute windows, two times a day in order to blast and not disrupt school. We had to close the highway next to it.”

They have also branched out to mixed-use developments that repurpose abandoned sites for office, retail and apartments, and to commercial projects.

Through it all, the knowledge and expertise they have gained continue to reap benefits.

“We're hitting that stride where the business is just walking through the projects,” Brian says. “We're attacking more and more difficult projects, larger projects.”

“Embracing Current Times”

Bob Dietz & Sons

Bob Dietz & Sons

“We had a rocky start,” Brian recalls. “It took us about six years going through dozens of young guys before we found one young man who really got the concept of what we were trying to do.”

Once they found that person interested in learning the business and growing a career, young employees seemed to follow. Those same young employees looked up to the first young worker, and they became motivated to succeed as well.

“For younger people, I think they see potential for growth,” says Tony. “And I try and point that out to them every day.”

The company has adapted to younger workers’ desire for more time off – even when it goes against their own work philosophy. That includes offering four-day work weeks.

“We've got about six or seven guys doing that now,” Brian says. “Instead of just saying, ‘No, we do a five-day work week and that's it,’ we've adopted that and allowed that to work into our company.”

He acknowledges that it’s not something he and Tony enjoy, but it has helped with retention. “It allows us to have guys that are extremely valuable still here instead of sending them down the road to go work for someone else, or maybe they go to have a complete career change.

“And that's just embracing current times.”

The company’s project growth has also aided in hiring experienced workers. Social media has played a big role, too, as more people see the work Dietz is doing and want to be a part of it.

“It's like a snowball effect,” Tony says. “As you get the new job, you also get the employees because they heard you got the job, and they're showing up.”

Employees also spread the word about the good working culture at Dietz & Sons, which brings in even more topnotch talent.

“We are trying to stand out in the community, stand out in the local contractor space and build something that is attractive,” Brian adds. “If you build something attractive, the people that belong in that space are drawn to it.”

Social Media Influencers

Tony and Brian Dietz at ConExpo 2023Bob Dietz & Sons

Tony and Brian Dietz at ConExpo 2023Bob Dietz & Sons

Around 2016, Brian began posting videos and photos on Facebook and Instagram of the company’s jobsites. Their projects were often in remote areas, so he wanted people to see the work they were doing.

“We started pretty slow, posting some videos,” Brian says. “It was exciting to have that engagement, for people to see it or comment on it. It just really started growing.”

Brian makes a point to focus on the company’s pride in its equipment and the fact that it is a family-owned business.

Brian and Tony have also used social media to display their family’s relationship with John Deere equipment, starting with their grandfather’s farming days. That has led the brothers to travel to various events as Deere ambassadors.

The brothers’ passion for leadership also comes through in their posts, most recently traveling to the Ariat Dirt World Summit in Houston, Texas, and letting their followers know of the things they learn.

“Social media has allowed me to mentor so many new contractors, even guys that are older than me that just haven't done things we’re doing,” Brian says. “It does take time to do that. However, there is a good feeling that you're helping somebody. Also, you kind of sharpen your own skill level.”

Above Industry Standards for Everything

Equipment World

Equipment World

“We had so many people that mentored us,” Brian says, “local contractors that were friends with my father, that really helped us as we were growing and as young guys, who shared things with us.”

One of the things they learned from their father was reinvesting in the business, especially equipment.

Most of their machines have less than 5,000 hours and are kept in immaculate condition. Operators are responsible for keeping equipment clean and greased. One employee – called the “cleaning manager” – goes around to jobsites with the sole purpose of deep cleaning the cabs.

“It's become part of our brand to be a step above industry standard in cleanliness,” Brian says. “The guys take pride in that, and then we're attracting a certain caliber of employee that wants to be in clean machinery.”

It helps morale, and the customers like it, too, he adds.

The above-industry-standard philosophy also holds for technology. The company introduced GPS machine control to its dozers and excavators in 2018 and hasn’t looked back. For the past five years, it has been using Engcon tiltrotators on its excavators. Telematics has been important for making sure the equipment stays in top running condition and making quick repairs to reduce downtime.

The company extends that technical knowledge to other contractors. Dietz holds an annual demo day at its headquarters, where contractors, dealers and anyone interested in construction machinery can come see and operate equipment.

“You're kind of paying it forward a little bit in that effort to share that technology and the efficiency and the benefits,” Brian says.

It also helps introduce young people to construction as a career. “You’re attracting the younger generation of kids and showing them some of the potential.”

Safety and communication also take high priority.

Toolbox talks are held each week on jobsites. Each morning, there is a jobsite briefing to go over the goals for the day and outline any safety hazards. At the end of the day, a debrief is held to go over the day’s results and performance.

Each Tuesday morning, the company holds a 20- to 30-minute Zoom meeting of all employees, with set agendas to discuss safety, maintenance and other issues.

Dietz has even established a companywide group chat for employees to point out lessons learned to help others or suggest better ways of doing things. Another group chat has been set up for maintenance matters.

On jobsites, everyone has two-way radios for keeping posted on issues, such as a truck entering or other safety concerns.

When it comes to safety, the company maintains yet another simple principle.

“We tell our guys, ‘If you took a photo of your job would you right now, or at any given time on your site, send it to OSHA?’” Brian says. If the answer is no, then fix it. Employees are empowered with that authority.

When it comes to being above industry standards, Brian and Tony take the same approach to their own leadership and goals.

“Some of that stuff is hard to figure out,” Brian explains. “You have these goals. You have these ideas, but you don't know how to get there. So we've been investing in ourselves as far as being good leaders.”

Meeting those challenges and setting a high bar for excellence keep the brothers excited and passionate about their work. It’s also part of the chain that links them to their past.

“Generations ago, good decisions were made, and it really has impacted us now,” Brian says. “And that's where I think a family business shines. With the right focus, you can really build for the next generation. And if they appreciate it and take advantage of those things, it can continue to be there.”