One of the keys to providing lower-cost machines is engine selection. Engines below 75 horsepower have less stringent emissions requirements under Tier 4 Final than do engines of more than 75 horsepower. The cost of meeting these less restrictive standards is lower, so the overall cost of a machine is lower.

Other strategies for lowering cost include having canopies as standard with cabs as options and offering performance-enhancing features only as options, or not at all. Telematics and a free multi-year subscription for their use have minimal effect on the cost of a machine and are standard on many down-spec models.

Because operators of lower-cost backhoes don’t want

The 310L EP has a tandem gear pump with one circuit for the front and one for the rear, while some other Deere models use a single pump. Having two dedicated circuits improves performance at both ends of the backhoe, says Brian Hennings, marketing manager for backhoe and tractor loaders at Deere.

Even so, there are applications where the lower power will be noticeable and customers whose work typically involves these applications should stay with higher-power machines. Examples include loading, roading and production work.

Rent spec right for more than rental

What OEMs often refer to as the rental market is much larger than rental and includes first-time buyers, owners—especially of large fleets, who never run their own equipment but instead rely on operators—and those seeking to fill gaps in their fleets.

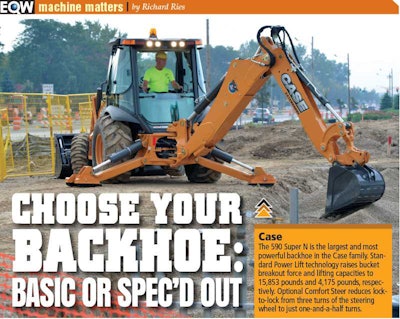

“The new Case 580N EP model, with its lower horsepower engine and basic standard offering, is ideal for the rental market but is also an excellent entry-level opportunity for that contractor who has thought about buying a backhoe but hasn’t pulled the trigger,” says Katie Pullen, brand marketing manager for Case Construction Equipment. “It’s also more practical for contractors to add to their fleets than more fully-featured models. It’s a great option for contractors seeking to grow their businesses.”

Although the 580N EP is relatively basic in order to meet the needs of the rental market, that’s not its only configuration. “Renters don’t want to pay for extra features,”

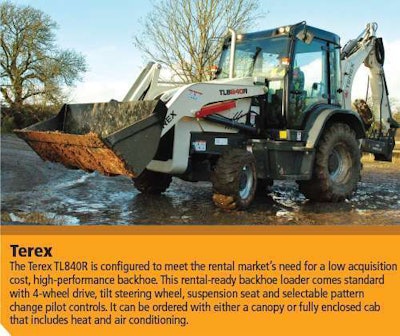

Even within the rental market, there are segments such as landscapers and site prep contractors, utilities and oil and gas pipeline construction, says Joe Turnage, product specialist with Terex Construction Americas. Down-spec models are simpler to set up and use for those who don’t run them every day and they’re priced right for rental houses. Those attributes make them appealing to other customers, says Turnage.

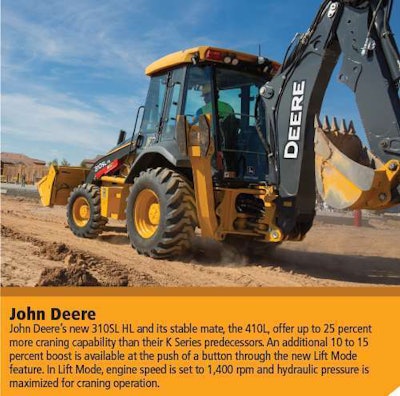

The type and number of standard features varies on rental-ready machines. Although Deere’s 70-horsepower 310L EP is considered a down-spec model, it still has as standard a 4-speed powershift transmission, a fuel-saving economy mode that can be configured independently for backhoe and loader functions, a multi-language digital monitor with full text diagnostic display and a three-year subscription service of JDLink telematics.

Right for you

So how do you decide whether a down-spec rental or full-featured backhoe is right for you? Turnage says those digging small trenches, swimming pools and septic systems will likely be happy with rental-spec machines. Those working in gravel pits or moving heavy loads such as rock or metal should look only at higher-spec machines with more power and heavier components.

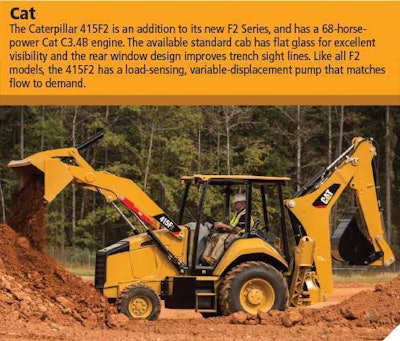

Kevin Hershberger, senior market professional of backhoe loaders for Caterpillar, says their 415F2 with 68 horsepower will hold its own against the company’s 87-horsepower 416F2 during backhoe operation. “But in horsepower demanding situations like aggressive front loader work or extended roading applications, the higher

On the other hand, not all customers use the full power available on their current machines, so a move to a lower spec machine doesn’t necessarily mean it won’t meet their requirements. It all comes down to matching machine performance with the customer’s needs.”

Heavy lifting

Some manufacturers are offering higher lift capacity options on their backhoes. John Deere’s 310SL HL and 410L have improved craning capabilities thanks to larger hydraulic cylinders and heavier rear structures.

Pressure-compensated, load-sensing (PCLS) valves are part of the design. “The PCLS valve has been improved to provide better feel and control, especially during multi-function tasks, such as curling the bucket with an auxiliary thumb while lifting the dipper,” says Hennings. Lift capacities of all other L Series models are unchanged from the K Series models they replace.

Pullen says the Power Lift technology available on most Case backhoes “has been one of the most successful and sought-after features in our product lineup. Power Lift channels hydraulic power directly to the boom while maintaining low engine speeds. It gives a 14-foot model lifting strength comparable to a 15-foot model, and a 15-foot model the lifting strength of a 7- to 8-ton excavator. It has also shown to improve dipper and bucket forces.”

Turnage says the North American market is changing and customers are often renting instead of buying. “Higher spec’d machines come with a higher price tag and therefore are not well suited to the rental market. Our TLB840R handles the majority of rental applications and is affordable for rental customers to both purchase and

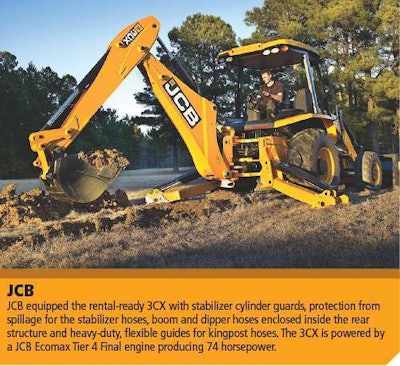

Just because a backhoe loader isn’t labeled as a high-lift-capacity machine doesn’t mean it doesn’t have that capability. JCB doesn’t designate any of its models as having high lift capacity, but looking at their numbers in the Equipment World Spec Guide shows their three 14-foot-class 3CX models have lift capacities of 3,509 pounds, comparable to other manufacturers’ high-lift-capacity 14-foot models and to some 15-foot models.

Turnage says higher lift capacities often reflect higher overall performance that may be important in other applications. He says even if lift capacity isn’t an issue, other related factors should be considered. “The biggest advantage of machines with higher lift capacities is that they also have higher breakout forces, the power needed to drive into a pile and to bring the bucket out of the pile fully loaded. These capabilities will benefit users who are doing production loading of heavy material, whereas most general users don’t need the extra capacity.”

Not everyone needs higher lift capacities from their backhoes. They may do little lifting and placing or they may have other equipment for those tasks. Owners of compact excavators of 5 metric tons or greater already have a machine that will out-lift most backhoes. “All that’s needed is lifting capacity to meet the application requirements of your backhoe business,” says Hershberger. “A high spec’d machine that delivers lift performance you never use doesn’t benefit anyone. So it’s really about making sure the machine you buy meets your actual working requirements.”

Fitting in

With such a wide range of power and features, it can be challenging to choose the right machine. The lower initial cost of a low-spec backhoe is appealing, but will it deliver the required performance?

“If customers do their homework and see that the specs of a lower horsepower model match their needs, they will not notice any significant lag in performance,” says Pullen. “Contractors accustomed to larger models with more features, however, will notice that these machines don’t have the full capabilities and features they’re used to. Heavy utility, oil and gas, and major highway all require greater lifting capacities, auxiliary hydraulics, heavier engine loads and some of the creature comforts that aren’t found in a down-spec unit.”

Hershberger says he encourages customers to consider some key points. What machine have they been using and how satisfied have they been with it? What type of work are they currently doing and how might that change in the next few years? Which features and performance items will help them do that work better, more efficiently or more cost effectively? “Our dealer salesmen understand our product and customer applications and can help customers identify critical requirements and the best machine to help them meet their needs,” he says.

The 3CX, 3CX-14 and 3CX-14 Super from JCB illustrate the range of standard equipment available within a given size of backhoe. All have 14-foot, 7-inch dig depths. The 3CX, targeted at rental and first-time buyers, has 71 horsepower, manual controls front and rear and tandem gear pumps. Rather than a variable geometry turbocharger, it is fitted with a wastegate turbocharger.

To enhance durability in rental and other demanding applications, the 3CX has metal fenders, a steel fuel tank, protection for the stabilizer cylinders and a wear strip on the dipper. Options include a hammer circuit (one-way flow), extending dipper, 6-in-1 front bucket and loader end pipe work (also called a third spool) to run power attachments. It is available with a canopy or cab; air conditioning is standard with the cab. The 3CX has a parallel lift design and 32.5-gpm hydraulics.

The 3CX-14 has an axial piston pump and higher flow. It has more available options than the 3CX, even an in-cab coffee maker. The Super model has all of these features plus higher horsepower, auto smooth ride to reduce bucket spillage and enhance operator comfort, auto throttle that returns the throttle to a pre-set when cycling through functions, auto drive (similar to cruise control) and auto check that performs all daily checks at key-on.

“By offering three levels of standard equipment with various options we can deliver an ideal machine for the rental, owner-operator and multi-unit fleet markets,” says Rafael Nunez, backhoe loader product manager with JCB. “They are distinct markets with different needs and our lineup reflects that.”

Terex offers the TLB840R as their rental version of the TLB840. The R model has 74 horsepower; the TLB840 has 88. But the R has 288 foot-pounds of torque compared to 281 foot-pounds in its predecessor so engine performance is good despite the lower horsepower.

The same hydraulic pump is used in both models so “the hydraulic power remains the same with our rental-spec’d TLB840R machine as with the full-spec’d TLB840 unit,” says Turnage. Depending on their needs customers may choose the TLB840R with a few options to meet the requirements of their applications, such as front or rear auxiliary hydraulics, and still have a lower initial cost than if they’re gone with the higher-spec TLB840.

Because of the diversity in specs and features, backhoe loader customers are advised to have a thorough understanding of their applications in order to select the right model for their needs. “In some cases customers who look closely at their current and future needs may even find that a different machine or a combination of different machines is a better choice for them,” says Hennings. But if a backhoe is the right choice, there are more models with a wider range of features available now than ever before.