Depending on applications and usage patterns, many sharp-pencil contractors have found a lot of value in compact wheel loaders.

And since it’s a fairly regular debate among contractors we also pulled some numbers on the O&O and production costs of skid steers to see how these machines stack up against a compact wheel loader. “It’s a proven fact the skid steer loader is a versatile machine due to its size, cost and capability,” Steger says. But the comparison is worth making. While compact wheel loader has a higher initial purchase price, in many cases it can provide lower operating costs and more cost efficient production than a skid steer loader. (See Compact wheel loader or a skid steer? on page 36.)

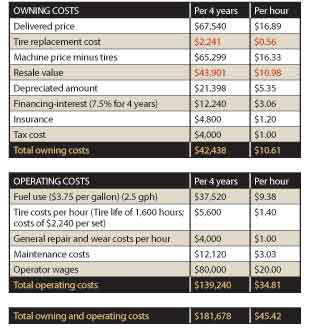

Keep in mind as we discuss these numbers that they are not actual cost figures, but generalized averages for discussion purposes only. Your choice of brand and options will have a big impact on the purchase price, and the harshness of your applications will make a big difference in your operating costs. To get a more accurate estimate, you should evaluate your specific application and consult with your local dealer to ensure you are providing the best comparison.

I. OWNING COSTS

Lifecycles

Compact wheel loaders are built with stronger frames and more durable components than many types of equipment in the in the compact arena and therefore have a longer life. While the owner of a typical skid steer loader may only keep the machine for four to six years, the useful life of a compact wheel loader is often eight to 10 years, Steger says. A realistic average and a reasonable number for calculation purposes for the compact wheel loader would be around 1,000 hours per year.

Purchase price

A TW65 size machine has an average suggested list price between $65,000 and $70,000 with cab, standard bucket, less tires, Steger says. The difference between the two prices is a result of options that the contractor chooses.

Financing/interest costs

There are a number of incentives offered by manufactures with good interest rates, Steger says. If you have your own source of financing or funding to purchase the product, you will often be eligible for an additional discount in lieu of using the manufacturer-backed financing.

Resale/residual value

“For calculation purposes I typically consider a residual value of 65 percent of the original cost after a four year period,” Steger says “Some markets may find better value retention while other areas may have depressed values, but if the maintenance is performed regularly and the equipment is kept in good condition these values are achievable.”

II. Operating costs

Average hours per year

Steger says he’s sees utilization rates ranging from 750 hours per year for landscape supply yards and general construction applications to 2,000 hours per year for refuse, recycling or agriculture applications. We peg our theoretical numbers on 1,000 hours a year, a figure that also allows you to easily calculate other scenarios such as 500, 1,500, or 2,000 hours per year. Keep in mind the slow economy has reduced compact wheel loader utilization and extended their (yearly) lifecycle over the past few years.

Fuel usage per hour

The Takeuchi TW65 has a published average fuel consumption of 2.5 gal per hour, based on 65 percent of full load. “Despite their size, compact wheel loaders are surprisingly efficient machines and able to use a smaller engine for propulsion, compared with a skid steer,” Steger says. Light usage may result in fuel consumption of approximately 2 gph while a heavy application may result in fuel consumption around 3 gph.

Tire costs/lifecycle

An OEM replacement tire for a compact wheel loader averages $575 to $650, so a set of four would run approximately $2,300 to $2,600, Steger says. The use of specialty tires to fit certain applications can drastically change this amount but may result in greater production or reduced downtime from flats or damage. Conversely, a set of lower quality tires may have a lower acquisition cost but could actually result in a higher cost per hour when you factor in tire life and downtime.

Tire life varies drastically with the application, operating style and even with tire construction but since compact wheel loader steering is performed by the frame articulation (rather than skidding the tires), tire wear is minimized and a conservative life span of approximately 1,500 hours is not uncommon.

Preventive maintenance

The average preventive maintenance cost for a compact wheel loader may seem comparable to other machine types, but in considering a purchase, Steger says reduced downtime and saving even just a few cents per hour on maintenance puts money back into your pocket over the course of owning the machine. He cites the TW65’s oil cooled engine (eliminates water pump problems, coolant hose failures and concern over the freeze protection in winter) and extended hydraulic oil drain intervals (with more frequent filter changes) as examples.

Close evaluation of the maintenance cost often results in a 6- to 12-percent savings compared to a skid steer, depending on the brand of machine and its technology, Steger says, which is why when you discuss O&O costs with your dealer, you need to review maintenance costs.

Ground engaging tools, bucket edge/teeth

Bucket cutting edge and hardware is approximately $300. The life varies greatly depending on the working conditions.

Cylinder repairs, other consumables

“I typically factor repairs into a wear-and-tear category that takes into account that repairs may be necessary after the warranty period,” Steger says. “By continually accruing a certain dollar amount or percentage of the machine cost you have an adequate amount banked up if an unexpected repair is needed. By saving year over year, you take into account that the warranty will cover early failures and later failures can be covered by your nest egg.”

Operator wages

We pegged this at $20 per hour, which theoretically includes benefits. The number you use will vary according to prevailing local wages or you may want to figure it differently if you are a sole proprietor or owner operator.

We are basing our calculations on a Takeuchi TW65 compact wheel loader used for four years at 1,000 hours per year. Note all these costs are general estimates for discussion purposes only. Your figures will vary depending on applications, soil conditions, operator skill, loads and maintenance. To get a more accurate estimate of your costs consult with a dealer. Also consult with your financial and tax advisors as any large capital purchase such as this will have tax implications and you may be able to depreciate considerable portions of the investment.

Compact wheel loaders cost from 15 to 50 percent more than a comparable size skid steer, depending on brand and features. And the skid steer with its low initial price, wide bucket and maneuverability, has found a permanent place in the pantheon of construction machines. But when some contractors do the math, a compact wheel loader can be the least expensive and most productive machine over the long term in certain applications.

The compact wheel loader excels at loading and moving material day in and day out, but the skid steer is more versatile. Before you make your next buying decision consider the variables.

A compact wheel loader uses a smaller engine to do roughly the same work. That results in fuel savings of up to 30 percent. Skid steers are hard on tires and will typically wear out a set twice as fast as a compact wheel loader. With the fuel and tire costs accounted a generic, 90-horsepower skid steer comes up with a total O&O cost of $49.46 an hour vs. $45.42 for the compact wheel loader.

In production loading applications the Takeuchi TW65 cited above can move 220 yards of material in an hour at $0.21 per yard. Our generic skid steer will move 139 yards in the same amount of time for $0.36 per yard, Steger says. Take that out to 1,000 cubic yards and the compact wheel loader does it for $206 vs. about $358 for the skid steer.

Just keep in mind there are more attachments available for skid steers, including box rakes, land clearing equipment, augers and site prep attachments. Skid steers can counter-rotate and work in confined spaces. And skid steers have a lower cab height for working under obstacles.