How equipment improvement process saved company $500,000 in maintenance costs

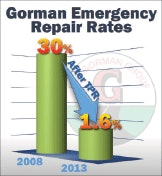

Nearly five years ago, The Gorman Group’s mechanics spent a third of its time fixing emergency breakdowns. That repair rate, while just a little more than the industry average of 30 percent, cost too much and created too much downtime for crews resurfacing and repairing roads in New England and the Mid-Atlantic.

Now, more than four years after embracing a structured improvement plan called Total Process Reliability (TPR), Gorman’s emergency repair rate has dropped to 1.6 percent at the halfway point this year, saving money and keeping crews on the job. To date, the company’s maintenance expenses are running about $500,000 less this year than last.

“We’ve gone through a huge transformation with accountability, morale and professionalism,” says Mark Gorman, who owns the New York-based company with his brother, Tony. “The difference is night and day. We are much more professional with how we handle equipment.”

The Gorman Group gives much of the credit for its success to TPR, a business approach to improve equipment efficiency and lower costs by changing how a company approaches maintenance and how it manages equipment. The goal is to get everyone in the company involved, standardize processes and collect information that will allow a company to reduce time and money lost on emergency repairs by engaging the organization in asset management. Keeping equipment working at its best becomes a companywide partnership instead of the maintenance department’s “problem.”

TPR builds on the work of Japanese engineer Seiichi Nakajima, who studied American preventive maintenance and developed the philosophy known as Total Productive Maintenance (TPM). TPM puts emphasis on quality and efficiency and is associated with manufacturers such as Honda and Toyota. TPR is the next generation of that process.

Implementing Total Process Reliability (TPR) lowered Gorman’s emergency repair rate to 1.6 percent halfway through this year, saving about $500,000.

Implementing Total Process Reliability (TPR) lowered Gorman’s emergency repair rate to 1.6 percent halfway through this year, saving about $500,000.“Preventive maintenance is like following the manufacturer’s recommendations for oil changes and car maintenance, but the detailed tracking of equipment failure allows a company to predict how long a part will last and find out how to extend the life of those components,” says Preston Ingalls, president/CEO of TBR Strategies. This Raleigh-based consulting firm helped Gorman implement TPR, studied the operation and provided recommendations to focus the company on fleet efficiency, increaseing vehicle uptime and lowering maintenance costs.

Ingalls recommended Gorman consolidate three maintenance facilities into one, as well as purchase a computer software system to track equipment failures and maintenance – which began a complete overhaul of its approach to maintenance. Fleet equipment generally is the largest single asset for construction companies, Ingalls says, making fleet efficiency a prime target for improvement. Gorman has more than 300 vehicles, from pickup trucks to paving machines.

“As a structured improvement process, TPR showed us we needed discipline and accountability,” says Joe Farone, chief financial officer of Gorman. He also says TPR benefited Gorman through documentation and giving them consistency. “Plus, employees now know what is expected from them,” he says.

Five years ago, Gorman did not have a preventive maintenance program, says Patrick Ryan, the company’s continuous improvement coordinator. The company started with two approaches – using the new computer software to track equipment maintenance and failures and creating a preventive maintenance program with responsibilities for both shop mechanics and equipment operators. The operator portion is called Operator Care, a process to build stewardship in the equipment.

A key component of TPR is holding the equipment operators accountable for upkeep. “Operators carry parts with them to do simple repairs on the jobsite and monitor their own equipment daily following a checklist and written standards,” Ryan says. “The results start to show because the equipment runs much better, and we are starting to see longer, more productive days on the job.”

Time is of the essence for Gorman because New England’s cold weather makes for a short season for road repairs, essentially from April to October.

Equipment manager Dan Corbett says he always tells the shop technicians to carefully examine the equipment, and a trends or patterns are noted.

Now that preventive maintenance is “ingrained in the company,” Corbett says he is focusing on making maintenance plans more detailed and specific to each vehicle.

For example, by tracking the repair history for Gorman’s Midland mix pavers (train pavers), Corbett saw the engines were lasting a little more than 24 months. Now the company replaces all train paver engines at 24 months, he says.

Corbett attributes the $500,000 savings in maintenance this year to this focus on preventive maintenance and to getting all of the shop employees and equipment operators involved in the service and welfare of the equipment. The company also started a second shift in the shop because many repairs happen at the end of the day, which reduced overtime spending.

Gorman’s procedures for handling tires demonstrate how data and training improve outcomes. In 2012, mechanics responded to 60 emergency calls for tire failures, so Corbett started a training program for equipment operators and gave them all tire gauges. Now, the operators are responsible for checking and recording tire pressure every day. Shop mechanics received training in recognizing tire wear and reading tire codes.

The work has paid off. So far this year, there have been only nine emergency calls for tire failures.

“Training does play a large role in everything we do,” Corbett says. “I think that’s imperative because then the guys know you’re investing in them, too.”

Every new hire at Gorman goes through TPR training, even if he or she will work in a supporting position. The company does refresher training every spring as employees gear up for the roadwork season.

The focus on organization and orderliness through a process called 5S — sort, set in order, shine, standardize and sustain — also results in cleaner equipment and a more appealing and orderly maintenance shop. Everything in the shop, and on each truck, is labeled, and there is a process for cleaning the equipment and shop each day. Every tool and every item have a home location.

Chip seal foreman Jim Brush has been working in the maintenance shop during the winter season for about 10 years and remembers it being different in the early days. “The garage was always dirty, dingy looking, dimly lit, and now it’s great going to work,” Brush says, adding that the commitment to orderliness and upkeep appealed to him because he was raised to take care of his equipment.

Gorman officials credit TPR for the maintenance improvements and believe the strategy has improved employee morale, customer perceptions and the bottom line.

“What we have seen this year has been the extreme positive feedback from our customers,” says Brian Jones, Gorman’s technical services/continuous improvement manager. “They are commenting on the appearance of our equipment and saying, ‘Your crew showed up, and they were ready to go.’”

Savings can be measured by calculating maintenance costs as a percentage of the equipment’s estimated replacement value. Currently, Gorman’s figure is 2.8 percent in an industry where the average is 15 percent and the best-in-class mark is 4 percent. The figure was 12.1 percent when the company started TPR.

Change is never easy, but having a structured approach allowed The Gorman Group to get on the road to becoming the best-in-class operation. “My advice to other owners? You’ve just got to go for it,” Mark Gorman says. He admits the company had its problems “for years but just didn’t have the guts to follow through. TPR is the best decision we ever made.”

About the author: Virginia Demaree Johnson is a freelance writer and editor based in Raleigh, North Carolina.