Meritor to launch all-new vocational trailer axle line

By Jack Roberts

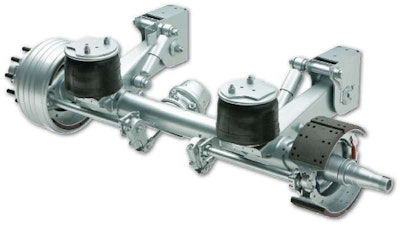

At a press conference at Meritor’s Frankfort, Kentucky, axle manufacturing facility, top company officials unveiled the all-new MTA Series of trailing-arm air ride trailer suspensions. The new line of axles is a clean-sheet design, specifically for vocational applications in North America such as platform, grain, tank, dump, chassis, bulk, specialty, lowboy and livestock trailers as well as specialty vans. According to Craig Frohock, general manager of Meritor’s Trailer Products division, the new series of axles completes the company’s lineup of trailer air suspension solutions while drawing on new technology and state-of-the-art manufacturing processes to deliver a durable, smooth-riding and flexible trailer axle.

Meritor’s pivot bushing technology absorbs vibration and delivers a smooth ride.

Meritor’s pivot bushing technology absorbs vibration and delivers a smooth ride.Rick Martin, director of training for Meritor, says the MTA Series features three key technology advancements. Chief among these is Meritor’s new pivot bushing technology, which absorbs road vibrations and shock forces while giving a smooth ride for improved cargo protection and reduced torsional stress on the trailer structures. Martin notes that Meritor engineers designed steel interleaf shims in the bushing, which provide improved fore-and-aft stiffness. This stiffness, in turn, aides in maintaining dynamic axle alignment for all the trailer wheels, resulting in improved tire wear and life and controlled roll steer.

Martin stresses that Meritor didn’t simply spec larger, more robust shock absorbers for the new MTA axle family. “These massive shock absorbers are so integral to the success of this axle design, we engineered our own proprietary shock absorbers specifically to insure the high performance of this axle,” he notes. “The resulting design is a shock absorber that is three times more robust and provides three times the dampening power of any competitive shock absorber on the market today.”

Additionally, Martin says the new shock absorber design includes a large bore for greater suspension control and more consistent tire contact with the road, which reduces tire while improving braking and handling characteristics.

The MTA axle series also features an axle wrap design which Martin says provides secure and durable axle connection to the trailer. This design also adds to the trailer’s overall suspension durability, according to Meritor engineers.

Although the MTA axle design is all-new, Martin says Meritor was able to draw heavily on existing, proven technology to insure superior performance. This includes a choice of Q Plus cam or air disc brakes, automatic slack adjusters, SteelLite X30 drums and lightweight hubs and the Meritor Tire Inflation System by PSI.

Frohock says the MTA axle family will include six basic models, including top-mount versions in 14- to 18-inch configurations and low mount versions in 6- to 18-inch configurations. “Meritor is currently working with our OEM customers to integrate the new axles into their product lines,” Frohock adds. “Production of the first axle model – the MTA23 – will begin this fall with production of additional axles ramping up through the remainder of 2010 and the summer of 2011.” EW