In the trenches

One of the most preventable accidents can also be the deadliest.

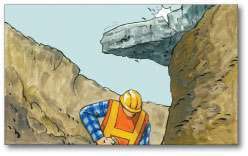

The accident: Three workers were repairing a water main break in a 7-foot-deep, 5-foot-wide excavation. To expose the water main, one worker working with a shovel at the bottom of the trench undercut the roadway. The side of the trench and the overhanging concrete collapsed – trapping and killing him.

Avoid the avoidable

According to the CDC, approximately 1,000 trench collapses involving lost time injuries occur each year – almost all of which are preventable. At least 75 percent occur where no trench system was used. Common systems include sloping, shoring, shielding and benching. Not all systems are appropriate for all trenches, and you must be trained in their use.

Danger from all sides

Train your onsite Competent Person how to select the right trench system for the job. This requires an understanding that many things can pose a hazard, including soil composition and activity around the trench. In this accident, for example, one contributing factor was that the water main break had saturated the soil, destabilizing the trench wall. Even if the soil is dry, operating equipment nearby creates vibration that can loosen soil and trigger a cave-in. Also, excavated soil near the edge of the trench puts additional pressure on the trench walls.

OSHA classifies soil as A (hardpan, caliche and clay), B (loam, sandy loam, silt and silty loam) or C (sand and running soil). You can determine the soil type with a penetrometer (which measures the unconfined compressive strength of cohesive soil), Torvane (which measures shear strength) or even a thumb penetration test (although subjective and less accurate than other methods). This in turn will help you decide on the appropriate protection system.

Once your trench protection system is in place, watch out for signs of potential problems:

Soil placed too close to the edge of the trench. A spoil pile slide or lip slide can cause a trench wall collapse.

Fracture lines in clay or layered soil. A fracture can indicate a shear wall collapse, which can rapidly bury a victim under thousands of pounds of soil.

Cracks and fissures near the bottom of the trench. Cracks indicate weaknesses that can lead to a belly slough collapse, which creates a difficult rescue situation because of the indentation in the wall.

From bad to worse

If you have a trench collapse incident, it’s dangerous to allow workers untrained in trench rescue techniques to attempt to rescue victims. Have rescue unit contact information available on site at all times. EW

Information for this Safety Watch came from an accident report, OSHA and the Center for Disease Control’s National Institute for Occupational Safety and Health. It is meant for general information only.