The 2018 Association of Equipment Management Professionals Technician of the Year graduated in 1989 from Universal Technical Institute in Chicago with an Associate of Science degree in auto and diesel technology. That quickly led to a job as a shop technician with West Side Tractor Sales, a local John Deere dealership. He progressed to field technician in 1995 and moved to Civil Constructors of Freeport, Illinois, in 2001.

Since he started collecting a paycheck, Fryer has completed numerous John Deere training classes, as well as regular classes and refresher courses at GOMACO, Blaw Knox, Etnyre, Caterpillar and others.

And like successful people everywhere, if he really gets stumped, Fryer knows who to call, having maintained good relationships with technicians and dealers throughout his career. “A lot of the guys I worked with helped me along,” says Fryer. “The guys I worked with at West Side Tractor were phenomenal.”

Fabrication wizard

Known around Civil Constructors as a fabrication wizard, Troy frequently builds parts to improve safety and productivity. Fryer’s supervisor, Greg Peet, president of Heavy Equipment Services and the equipment manager for Civil Constructors and the other Helm Group companies, likens him to MacGyver.

“Fryer demonstrates the ability to keep equipment running on the job at all times, regardless of whether or not the right parts are on hand or available,” he says.

And Fryer doesn’t just fix equipment. He uses his skills to make it better. On one occasion he fabricated a guard for a rock saw with an 8-foot diameter to protect coworkers from flying debris.

“I didn’t want to see somebody get into that big rock wheel,” says Fryer. “So I asked my boss if it was all right and proceeded to build a hydraulically moveable guard. When you set it in the ground, the whole shield lowered down almost into the trench.”

The guard contained flying debris and left no chance that workers or their tools could inadvertently come in contact with the spinning blade. Another safety improvement: Fryer fabricated a guard around the conveyor belt on a road widener to keep the dump man out of harm’s way.

Fryer also fabricated a crack filler chute for a road widener. This enabled the widener to perform tasks that would otherwise require a skid steer and hand work. This particular phase of the project was bid at 465 man-hours, but with the modified machine, crews completed the task in just 35 man-hours – a huge win for the company, says Peet.

People person

In the soft skills department, Fryer maintains a good attitude and works well under pressure, says Peet. He can communicate with everybody on the team, office staff, other technicians, field foremen and operators.

“Troy is a huge part of our division,” says Steve Rhode, paving division of Civil Constructors. “He’s there early every morning to get us started, and before he leaves at night always checking in.”

Terry Diehl, Heavy Equipment Services, has worked with Troy for 15 years. “On everything we throw at Troy to repair or work, he has always done a great job,” he says. “He’s a great mechanic and fabricator.”

Versatile skills, challenging jobs

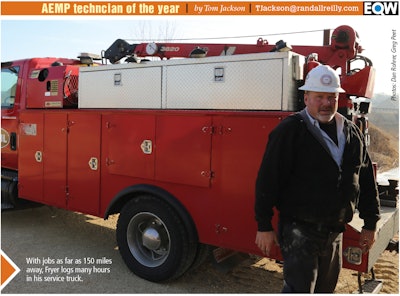

At Civil Constructors, Fryer deploys a wide range of skills to keep the company’s asphalt and concrete paving equipment in tip-top shape and to repair and maintain the general construction equipment. These include hydraulic troubleshooting and repair; electrical troubleshooting and repair; welding repairs and fabrication; and engine and powertrain rebuilds, including transmissions, torque converters, drop boxes, differentials and final drives.

When it comes to today’s equipment, he finds some aspects of it easier to deal with, and some harder.

Accessibility is getting better, Fryer says, but electronics are becoming more challenging. “A lot of times you have to have the dealer come out and diagnose it,” he says.

Yet often when a machine throws a code, it’s not a problem that requires a software engineer. “A lot of the problems we find are when wires break inside wiring harnesses, and the computer doesn’t do much to help you with that,” Fryer says. “You just have to dig in and start troubleshooting your harness.”

Tier 4 Final emissions systems are perhaps Fryer’s biggest challenge. “When a machine derates because of an emissions problem, it’s never at a good time,” he says.

Racing fans

It’s not surprising that with his mechanical skills and know-how Fryer has taken an interest in auto racing. Fryer raced back in the 1990s and passed that love of speed onto his son, Jaden, who began racing go-carts at age 3.

Jaden, with his dad as chief mechanic, has racked up an impressive string of trophies. “One year Jaden had three track championships and 60 feature wins when he was 7 or 8 years old,” says Fryer. And last year at the age of 14, he came in second in the IMCA Sport Mod Rookie of the Year competition.

The goal is to move Jaden up to the big leagues, perhaps NASCAR or Formula racing. “At some point we’ll probably run out of money,” says Fryer, “but we do have some really great sponsors, and without them, we couldn’t do what we do.”

The AEMP Technician of the Year is sponsored by John Deere and Equipment World magazine. If you or a technician who works for you is interested in applying for the AEMP Technician of the Year program, go to: https://www.aemp.org/page/ToY. You do not have to be a member of AEMP to be eligible.