Advanced telematics

Making the case for moving into full-featured systems from third party providers

By Tom Jackson

The four data sets in the new standard include:

• cumulative operating hours or

• cumulative miles

• cumulative fuel burned

• current location

So if you can get this data rolled into the fleet management program of your choice, does that eliminate the need to standardize your fleet with just one brand of telematics device?

The answer depends on what you want to accomplish. “It is not really one size fits all. The decision to deploy a single or multiple fleet management solution depends on the needs you have across your entire fleet and how well specific technology options can be applied to each of those needs,” says Rob Painter, Trimble’s business area manager for heavy and highway solutions.

“You shouldn’t be getting a telematics system just for the heck of it,” says Tony Nicoletti, director of sales, DPL America. “Know what you really want to get out of the system, and what your measurable return will be before you invest in the technology.” You should be able to run the numbers ahead of time and determine how you can benefit from the data and how quickly the system will pay for itself, he says.

Beyond the basics

The four data types standardized in the AEMP protocols cover a lot of what many equipment managers need. But that’s still just the basics, and telematics programs can offer you a whole lot more. Or to look at it another way, the standard stops just where the fun begins.

“If you want more specific machine oriented information you can use sensors – for example, to measure how often a truck dumps its bed,” says Ron Ludchak, director of global sales for Topcon Tierra. “I have one customer who uses a sensor to measure the grease level on an auto-lube system on a hammer. It shuts off the hammer when it gets too low and sends an alert to the dealer. I also have customers who use sensors to monitor the air cleaner indicator on a machine. If you talk to 15 different customers you’ll probably find 13 different ways they want to use sensors,” he says.

Some of the more popular applications and benefits include:

Measure work. Telematics systems can be set up to measure work vs. idle by tracking the movement of a dozer, scraper or artic, Ludchak says. For machines that work in one position, such as an excavator, you can monitor pilot pressure or rpms. And once you can measure work, it’s not hard to monitor cycle times and study how efficiently your trucks and loading machines work together.

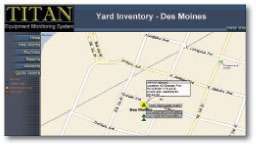

Geofences. The AEMP standard will show you the machine’s location. You can take that function a step further and set up a geofence or curfew. A geofence will shut a machine down, or send you an alert if the machine moves outside a boundary line you establish. Curfews do the same thing, essentially, rendering a machine inoperable after certain hours.

Truck dispatching. If you run dump, concrete or asphalt trucks, telematics devices will improve dispatching and the routing of service techs, says Nicoletti. And having your trucks on the same system as your off-road equipment cuts out a lot of confusion and wasted time. “Getting them on the same mapping interface – a single source – prevents you from having to jump from one website to the next,” he says.

Versatility. The bigger OEMs today offer telematics standard or as an option on their major machine lines. But small equipment like skid steers and compact excavators or specialty machines like trenchers and directional drills won’t have telematics on them unless you install the system yourself or have the factory or dealer do so as a special order. Theft prevention is a major reason why contractors are putting telematics systems on machines – such as light towers and compressors – that wouldn’t otherwise have them.

GPS tracking through telematics systems allows you to see where your trucks and equipment are in real time.

GPS tracking through telematics systems allows you to see where your trucks and equipment are in real time.Portability. Aftermarket telematics hardware can be moved from one machine to another. “You can’t do that on an OEM system. It’s part of their machine and it goes with it,” Ludchak says. “We even have customers who keep units on the shelf to put on rental machines.”

Machine health. “A third party telematics system website can let you monitor the health of your entire fleet of machines – including temps, rpms, oil pressure – regardless of brand. It’s our belief that customers don’t want to go to five different screens to manage their machines,” Painter says. “If the customer wants to give us the data feeds we can integrate that data into our software application and consolidate their view of the fleet.”

“We can create a universal interface where we have eight additional inputs to track a variety of different functions, and we can make it flat across all the different manufacturers’ makes and models,” Nicoletti says. “You can say: show me my idle time on this job or on all these excavators for the quarter, regardless of manufacturer.”

Data for analysis. “With a single brand of telematics you gain the benefit of needing only one website to go to access all your information, and you get a consistent output of information,” Painter says. “You can also get a wide range of services depending on what you sign up for.”

“We store the data indefinitely as part of the subscription so you can go back two days, two weeks or two years and run the analysis,” Nicoletti says. “Customers can run reports manually, customize what they want, download it into Excel spreadsheets or pull it into their own business systems via a SOAP (simple object access protocol) interface. We also automate delivery where a report runs itself saves as a spreadsheet, and the system will send them an e-mail at a designated time. For example the shop gets the e-mail at 6 a.m. every Monday morning and they have all the information they need to do their service scheduling for the week.”

“We allow back office software to come in and grab the data they need,” Ludchak says. “We do it primarily through XML but you can also do it though APIs.” (XML and APIs are open architecture software programs that make it possible for two different programs to communicate in a common language.)

Acquisition strategies. Acquisition can be as simple as buying a unit and putting it on your machine, or as involved as high level corporate meetings.“CFOs are often as involved with buying and implementation decisions as the fleet managers,” Painter says. “And then if you get more into the customer’s enterprise resource planning systems, we’re typically partnering with their IT people.”

In determining pricing, there are two components – the hardware and the software subscription service, which typically offers a number of options to choose from. “It could be a high-end hardware platform that’s needed to deliver a richer set of information, or it could be lower priced hardware that’s delivering more of just a dot on the map – hours and location,” Painter says. Likewise with the subscription services that let you access a website with your information on it. “The more data elements you’re pulling through, the more you’ll pay,” he says.

If you work in climates or applications that shut down your machines for certain times of the year, you should look into a system that doesn’t charge you the service fee for all 12 months out of the year. “Customers who do seasonal work can deactivate a unit if they’re down four months out of the year so they’re not paying for sitting machines,” Nicoletti says. EW

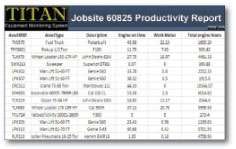

Telematics driven reports

Telematics systems integrate into fleet management and back office software programs to generate a variety of reports.

Telematics systems integrate into fleet management and back office software programs to generate a variety of reports. By learning which machines work the most and which the least you can readjust your machine mix on a job to maximize cost effectiveness.

By learning which machines work the most and which the least you can readjust your machine mix on a job to maximize cost effectiveness. Reports on fuel burned by asset help you monitor one of your biggest expenses.

Reports on fuel burned by asset help you monitor one of your biggest expenses.