Announcing that it was “seriously moving into the telehandler business,” Linamar’s Skyjack division debuted its “clean sheet design” four-model TH series telehandler lineup at World of Concrete, emphasizing simplicity that still packs a performance punch.

All four models use 74-horsepower engines and yet two of the models still deliver 50 percent-and-above potential grade ability with no increase in hydraulic function times.

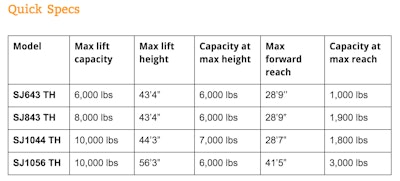

The models range from the 6,000-pound, 43-foot-reach SJ 643 TH to the SJ 1056 TH, a 10,000-pound machine with 56 feet of reach. Compared with previous models, the TH range offers simpler rear axle stabilization, hydraulics systems, outriggers, controls, engine servicing and electronics.

Using a common manufacturer strategy of keeping engine horsepower below 75 horsepower—the level at which additional emissions reduction requirements kick in—Skyjack avoided the addition of a diesel particulate filter (DPF), and the use of diesel exhaust fluid (DEF) and other exhaust after treatment components.

“Even though we went from 110 to 74 horsepower, we were able to get the pound-foot torque performance we needed,” says Barry Greenway, Skyjack product manager. “The only trade off was in top speed, which dropped from 20 mph to 15 mph. But companies told us they didn’t want operators driving at those speeds with a full load, anyway.”

Rental customers that require additional speed can opt for a 107-horsepower engine on the two 10,000-pound models that just requires a DEF after treatment system.

The TH range has a standard Readyhook yoke-mounted lifting hook, capable of lifting the maximum lift capacity of each model, allowing safe under slinging of loads and offering a better alternative to using forks as an underslung lifting device.

Since most telehandlers go into the rental market, Skyjack created a flexible cab enclosure system that allows owners to easily switch between open and closed cabs. All glass surfaces are flat, with bolt-on fasteners. “If a customer breaks a pane, it’s easy to replace,” Greenway says. “And if he’s moving a machine from the South to the Northeast, he can easily switch from a canopy to an enclosed cab.”

Transmission development

Skyjack also announced its partnership with CVTCORP, manufacturer of mechanical continuously variable transmissions (CVT). The two companies are working together to develop an optional CVT for the TH series.

“This allows us to provide an innovative, yet proven, optional transmission that optimizes telehandler performance and life span,” says Brad Boehler, Skyjack president. “The infinite number of ratios provided by the transmission will enable these models to do more work with less fuel.”

CVTCORP is currently testing a TH series-specific CVT transmission that will eliminate the need for the operator to shift gears.

“This protects the machine from abuse and saves fuel costs by ensuring the engine can always operate in its peak efficiency range,” says Daniel Gerard, CVTCORP president and CEO. Expanding on the “protect from abuse” statement, as an example, Greenway says an operator can shift into reverse while traveling at max forward speed with his foot firmly on the accelerator and the transmission will respond by smoothly decelerating and seamlessly transitioning into reverse.