Work Zone Woes

The busier the zone, the greater the risk

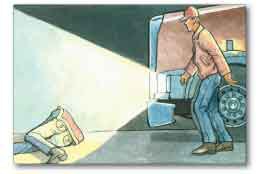

The bottom line: A post-accident investigation determined that the worker, who had been on the job approximately three months, was not assigned to be in the work zone at that time. Normally assigned as a flagger and with no training on work zone safety, the worker had apparently been shoveling spilled asphalt and had his back to the vehicle when he was hit. He did not see or hear the truck, although the truck’s lights and backup alarm were in good working order. The driver said he used his driver’s side mirror to align the truck with the paver and failed to see the worker, who was struck by the truck on the passenger side. The investigation also determined the work zone was not properly illuminated, and the spotters assigned to the area had already moved to the next section of roadway to be paved when the accident occurred.

Follow the plan

Work zones are heavily congested areas. Your employer will have a plan in place that will minimize any confusion created by the heavy traffic. Become familiar with the procedure and follow it to the letter.

Backing procedures. Use both side mirrors when backing, and make sure a spotter is on hand to help you with blind spots. Don’t back up until you receive an all-clear signal from the spotter.

Traffic routes. The general contractor will have established a traffic route for the work zone. Other workers are counting on equipment operators and truck drivers to adhere to this route. If you’re on foot, avoid the path of truck and equipment traffic.

Cameras and sensors. Use the tools available to you. If your vehicle has an aftermarket sensor or backup camera, you can use these to monitor blind spots.

Illumination. Although OSHA requires a minimum of 5 foot-candles for a general construction area, the National Cooperative Highway Research Program recommends a minimum illumination of 10 foot-candles for paving operations.

Safe locations. Don’t complete any hand work while equipment is in operation. Remain with the rest of your crew in a safe location until the area is clear of machines and vehicles.

Information for this Safety Watch came from an accident report, OSHA, the Center for Disease Control’s NIOSH program and the National Cooperative Highway Research Program. It is to be used for general information only.