Survival of that infrastructure points to the high resiliency of continuously reinforced concrete paving (CRCP) after flooding and other disasters, says Elizabeth Lukefahr, executive director of the Texas Concrete Pavement Association.

“When the waters receded, other than cleaning up debris, there was no repair of any (CRCP) section of Texas DOT’s pavements in the city that were flooded,” says Lukefahr. For many of those pavements, it was the third time they had flooded in 15 years.

In a state already committed to CRCP as its primary concrete pavement, the freeways’ ability to weather the flood brought a fresh look at why spending more upfront to install CRCP makes sense, says Lukefahr.

With Texas, Illinois and California leading CRCP use, other states are beginning to incorporate it, such as Virginia, Oklahoma and New Mexico. Indiana recently used CRCP – which requires less concrete thickness compared to jointed plain – to rebuild the interstate pavement under a bridge that needed higher clearance because it kept getting hit by trucks.

Lukefahr says the resiliency of CRCP can be critical, not just in flooded areas, but also for roads with heavy truck traffic. And in areas with wildfires, it will fare much better than asphalt, she says.

“Those TxDOT CRCP sections in downtown Houston have performed better under those extreme weather events than most people would have otherwise predicted,” says Lukefahr, a former concrete and concrete pavement engineer with the Texas Department of Transportation.

Texas DOT officials confirm that repairs weren’t needed for CRCP.

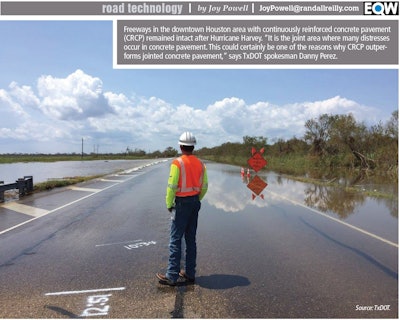

“We are not aware of any issues with the CRC pavement occurring after waters receded following Hurricane Harvey,” says Danny Perez, public information officer for Texas DOT.

“It is the joint area where many distresses occur in concrete pavement,” Perez explains. “This could certainly be one of the reasons why CRCP outperforms jointed concrete pavement.”

There’s no comparative data between flooded CRCP sections of Texas DOT pavements and other jointed and flexible paving, according to the agency. One reason: all of metro Houston’s main lanes are CRCP.

The Texas Concrete Pavement Association is working with the Texas A&M Transportation Institute to document CRCP performance and cost data. One goal of the research is to encourage engineers to factor pavement resiliency into their decisions.

“This resiliency topic can be tailored to whatever the most immediate threat is in your geographic area,” Lukfahr says. Owners may start recognizing resiliency to extreme weather as a decision factor, perhaps leading to more CRCP in evacuation routes, she adds.

Several states incorporating CRCP

Even though CRCP tests in 1949 and 1971 were successful, California stuck with jointed plain concrete pavement (JPCP). But CRCP’s minimal repair and rehabilitation advantages have led California to return to it in the past decade, and other states are following suit.

The Federal Highway Administration is working with several states to advance CRCP use, says Sam Tyson, FHWA concrete pavement engineer.

“A significant new project on NM 136 will carry high volumes of heavily loaded truck traffic from an international border-crossing from Mexico to a rail facility north of the border in New Mexico,” Tyson says. The year-long project began last October, with CRCP construction slated for Spring 2018. Total project cost is $47.6 million, of which nearly $22.7 million is for CRCP, according to Benito Trevino of the New Mexico DOT.

States interested in incorporating CRCP have sought advice from TxDOT officials, who have shared specifications, design standards and programs.

Says Lukefahr: “There is a tremendous application, even in Texas, for jointed pavement, and obviously, certain other states think that jointed pavements are a better solution for them than CRCP. But in fair-weather states, the ability to continue the life of the CRCP is more attractive than continuous repair and maintenance of jointed sections on busy roadways.”

For decades, Texas has documented CRCP’s better long-term performance, smoothness and resiliency under heavier traffic. Experts say it offers more rehabilitation options than jointed concrete, in part because anything put on top of it does not have to contend with joints underneath. Texas DOT has used bonded concrete overlays extensively to double the pavement’s 30-year life to 60 years of performance.

Higher cost yet more durability, strength, longevity

In Texas, the nation’s energy capital, there are plenty of freight trucks, and some interstates already have more allowances for heavier vehicles and chained vehicles.

If a road has a lot of 18-wheel trucks, CRCP will be a better long-term performer, according to Lukefahr.

Texas A&M Transportation Institute has been studying impacts of truck drafting, or platooning, to reduce wind resistance. The trucking industry is working with Texas DOT on having the lead vehicle operated by a conventional driver and vehicles trailing electronically. But these platoons impact pavement, which has no opportunity to rebound between sets of axles. Under that pressure, CRCP would fare best of all the pavement types, Lukefahr says.

“Continuously reinforced really is the workhorse, heavy-duty, long-lasting pavement,” she says.

CRCP does sustain a number of cracks, with a transfer of crack in spacing anywhere between 2 and 6 feet. But she says that “because all of that reinforced steel is there, those cracks remain very, very tight, and so it’s not a problem from a durability aspect.”

Illinois Tollway studying use of CRCP for 50-year design

In a $4 billion expansion of the Illinois Tollway’s most congested stretch, CRCP is being eyed for possible use on 22 miles of I-294 stretching from O’Hare International south to 95th Street, a tollway spokesman says.

The privately funded tollway has been looking into CRCP because of its zero-maintenance and longer life, according to Mike Plei, an Illinois-based consultant who served on a research committee that built test sections for the massive project.

Illinois has used CRCP for years, and the cracks don’t get wider or deteriorate, says Plei.

With jointed pavement, Midwestern states have experienced deterioration in joints. That is partly from using de-icing chemical solutions, and temperature effects moving the concrete, Plei explains. The Concrete Pavement Technology Center at Iowa State has determined a way to mitigate that problem, “but unfortunately, susceptible projects have already been built,” he says.

“There’s a lot of research on reducing the use of joints because that’s where the problems come in, and with CRCP, you can pretty much eliminate the joints.”

Contractor considerations

Because of CRCP’s price and relatively new use, a lot of transportation agencies and contractors stay with what they know – jointed plain pavement, says Bill Davenport, spokesman for the American Concrete Pavement Association (ACPA).

“We’re using dowel bars and tie bars, so we are using steel, obviously, in a lot of our concrete pavements, but the jointed plain is probably the most prevalent,” he says. “That has to do with cost but also the experience of the contractors with that type of pavement.”

But Gerald Voigt, ACPA’s president and CEO, doesn’t see much difference between jointed concrete pavement and CRCP. “In fact, CRCP can be a more uniform placement since the steel is continuous, and with jointed concrete pavement, there are dowel baskets every 15 feet.”

“The learning curve is probably more about steel placement, splicing and fastening,” Voigt adds. “Vibration is one consideration, so the contractor has to have this set up properly to ensure quality, since the vibration has to get consolidation below the steel.”

Eric Ferrebee, ACPA technical service engineer, says a consistent mix must be properly consolidated.

“The consolidation is key for CRCP, as the concrete needs to adequately bond to the steel for proper performance,” Ferrebee says.

Plei, who has viewed most CRCP projects in the nation, says he’s met Texas contractors who love CRCP and won’t build jointed pavement. He notes that Texas hit a record in August with 1 million square yards of CRCP bid.

Because of their vast experience and other factors, Texas contractors also tend to build at much lower prices than in the rest of the country, Plei says.

“The Texans are so used to building it, they do it efficiently,” Plei says. “For the contractors outside of Texas who build maybe one CRCP (project) every 10 years, the crews need to pay attention a little more.”