Articulating a Difference

Doosan’s rebranding of the Moxy truck keeps all the unique engineering of the original design and brings it up to date with new technology

Since the early 1970s Norwegian truck manufacturer Moxy offered a different mechanical design in the world of articulated trucks. And while the truck was well regarded, more recent changes in ownership left the company without sufficient resources to maintain the market share it enjoyed previously in the United States.

Access over the front tire make makes the climb into the cab safer and easier.

Access over the front tire make makes the climb into the cab safer and easier.But those limitations began to change in late 2008 when Doosan Infracore America bought Moxy Engineering and put in place a plan to bolster the truck’s marketing and parts availability for the U.S. contractor. Doosan showed the DA40, the first in a new family of articulated trucks to the press this summer and will begin selling them in the first quarter of 2012. Originally dubbed Doosan-Moxy, the new trucks will be branded the Doosan DA Series. The mechanical configuration of the Doosan truck enabled it to maintain ground contact with all six wheels 100 percent of the time, for traction, power to the ground and stability, says Brian Bereika, Doosan articulated dump truck product specialist. Features include:

Mounting the turning ring forward of the articulating joint and steering cylinders makes the cab more stable.

Mounting the turning ring forward of the articulating joint and steering cylinders makes the cab more stable.• The turning ring allows the front frame to move independent of the rear frame. All artics have them, but in the Doosan the turning ring sits in front of the articulation joint, rather than behind it. Doosan says this keeps the weight evenly balanced 50/50 on the two front wheels even when turning a loaded truck.

• Tandem housing. Traditional artics have three pairs of wheels and each pair has its own differential. Doosan’s driveline has a differential for the front wheels but the two pairs of wheels under the truck bed are served by just one differential and linked fore and aft by an oil bathed gear box much like a bogie system on an undercarriage.

• Limited slip differential. Locking differentials are either 100 percent locked or not. Doosan opts for a limited slip diff with a 45 percent locking ratio so the differential automatically sends torque to the side with greater traction. The benefit is that the driver doesn’t have to decide when to lock or unlock and can concentrate more on driving.

Independent front suspension gives you a smoother ride and helps keep the tires planted firmly on the ground.

Independent front suspension gives you a smoother ride and helps keep the tires planted firmly on the ground.• Longitudinal differential. Conventional artics offer you the ability to lock all three differentials or any combination of the three – lots of choices but also lots of decisions for the operator, too. Doosan’s longitudinal differential offers you a simpler choice of unlocked (one-third of the torque to the front wheels, two-thirds to the rear) or 100-percent locked. It also keeps the design simpler by eliminating the need for an electronic traction control system.

• Independent front suspension. Just like a sports car, the two front tires on the Doosan artic move up and down independent of one another with 16 degrees of total oscillation.

ENGINE

A steeply sloped bed lowers the center of gravity and eliminates the need for fat tires.

A steeply sloped bed lowers the center of gravity and eliminates the need for fat tires.The six-cylinder, Tier 4 Interim, Scania engine puts out 500 horsepower at 2,100 rpm. This gives the DA40 a 10-percent increase in power and a 22-percent increase in gross torque (1,750 foot-pounds at 1,300 rpm) compared to the previous MT41 model.

The engine uses selective catalytic reduction or SCR to reduce emissions. This requires the addition of diesel exhaust fluid (DEF) that is periodically added to a dedicated onboard tank. The DEF is injected into the exhaust stream to reduce emissions, and while there is more hardware for this than non-SCR engines, SCR engines improve fuel economy and run cooler. Doosan claims an 8-percent improvement in fuel efficiency with this new engine.

BRAKES

There are four brake systems on the Doosan artic:

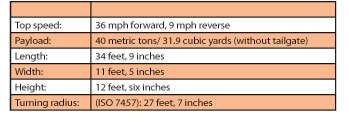

Vital Stats

Vital Stats• An engine exhaust brake is the main source of stopping power and kicks in whenever the operator’s foot comes off the accelerator.

• The operator can manually activate a hydraulic retarder in the transmission whenever the exhaust brake is not enough.

• Multi-disc, enclosed wet brakes are engaged by pressing the foot pedal, used for short periods only when required.

• Disc and caliper parking brakes mounted in line on the driveshaft secure the truck when stopped.

CABIN

• Rubber mounts for the cab, and large hydro-pneumatic cylinders in the suspension isolate the driver from vibration and shock.

The tandem housing links the rear wheels together in a bogie-like arrangement for improved stability and traction.

The tandem housing links the rear wheels together in a bogie-like arrangement for improved stability and traction.• The cab controls and dashboard have been updated for ease of use.

• Two small hydraulic shocks and one tall rubber spring on each side of the cab isolate the leading suspension arms from the front frame.

• The cab tilts up for easy access to service points.

• The access ladder to the cab is angled toward the rear of the truck – you walk up the side of the cab in front of the tire rather than straight into it – making getting in and out easier and safer.

• Oversized mirrors improve visibility to the rear tires and since they’re heated they won’t fog up or ice over in cold weather.

SERVICE INTERVALS

• Engine and oil filters: 500 hours

• Transmission oil and filters: 1,000 hours

• Hydraulic oil: 4,000 hours

ADDITIONAL

• “Over vertical” protection prevents the dump body from going beyond vertical when dumping on slopes.

• A sloping rear frame lowers center of gravity making it unnecessary to use wide, low profile tires.

• The bed comes standard pre-plumbed with channels that route hot exhaust into the metal and keep it warm enough to prevent material from sticking in freezing temperatures. Customers that need this feature only have to order and install an optional kit that diverts a portion of the exhaust heat to the bed.

• A tailgate option can be ordered for loose material retention.

• Standard auto-lube system eliminates most greasing chores.

• New vehicle control unit (VCU) sends all machine vital signs and error messages to a large in-dash LCD display. Laptop plug-in ports are also available for quick system diagnostics.