When the tread wears thin you can print a new one on top of the old.

When the tread wears thin you can print a new one on top of the old.It looks strange and the first applications may be a decade away, but I have a suspicion this 3D printed concept tire from Michelin might eventually be coming to a loader near you.

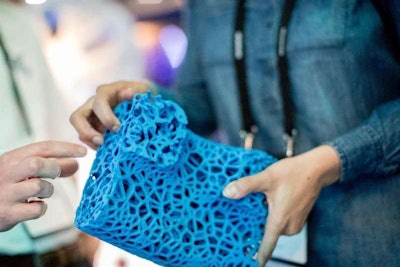

Michelin calls it the Vision tire. As you might deduce, it’s airless. No need to inflate it or worry about inflation pressures. That also means it can never go flat. It also doesn’t need a rim or steel wheel to secure it to the axle. The lacy web of material is arrayed so that the tire gets stronger and more rigid toward the center while remaining pliable and shock absorbing at the perimeter. Sensors imbedded in the material give you real time information about its condition.

Michelin unveiled their concept tire in Montreal this summer at Movin’ On 2017, a three-day event covering the future of transportation technology.

Michelin unveiled their concept tire in Montreal this summer at Movin’ On 2017, a three-day event covering the future of transportation technology.The Vision tire is also made from bio-sourced and bio-degradable materials including food scraps, cardboard, hay, paper and metal. And it’s what the company calls “rechargeable,” meaning once the tread wears out to the minimum depth, you can print out a new tread belt on top of the old one.

This feature could potentially be a boon for earthmovers. If you change jobsites from soft sand or dirt to abrasive rock and gravel, you can print out the appropriate tread—wear resistant or traction enhancing—and reload the carcass with the optimum tread for the jobsite.

Michelin introduced the concept at Movin’ On 2017, a three-day event focused on solving society’s mobility challenges. Prior to the reveal, Michelin held a series of panel discussions about transportation technology with people around the world. What they learned was the people wanted to see environmental responsibility, hence the biodegradable and rechargeable nature of the tires.

Disposal of used tires is one of the biggest challenges in the industry. In the United States alone, 290 million used tires are disposed of every year. Even though some 233 million of these are recycled, retreaded or reclaimed in some fashion, the storage, handling and disposal of tires is a logistical headache.

While the commercial release of the Vision tire may be a decade away from fruition, Michelin has already introduced an airless tire for skid steers. Called the Tweel, it’s a solid rubber construction with a web structure that connects the tread to the axle. The webbing reduces weight and gives the tire some flex for traction and ride quality. The Tweel is used primarily by contractors working in scrap yards, recycling and demolition projects or applications where punctured pneumatic tires are a problem.

The 3D printing process spins a web of material that is strong but light, rigid in the center and more flexible towards the outer rim of the tire.

The 3D printing process spins a web of material that is strong but light, rigid in the center and more flexible towards the outer rim of the tire. The Vision tire is both bio-sourced and bio-degradable and can be created using a variety of organic materials.

The Vision tire is both bio-sourced and bio-degradable and can be created using a variety of organic materials.