Rollers compact the 50-percent RAP mat on Manitoba PTH 8.

Rollers compact the 50-percent RAP mat on Manitoba PTH 8.Half and Half

One year later, a mat with 50-percent RAP looks really good.

by P. Michael Harnsberger,

Western Research Institute

All photos courtesy of Western Research Institute.

A stretch of asphalt in Canada, laid down in September 2009, is beginning to reveal its secrets.

Initial tests on the road included examination of a section which used 50-percent Reclaimed Asphalt Pavement (RAP) provided by the old road it replaced. The first results are positive. And that’s good news to proponents of using higher percentages of RAP, a process which had environmental (fewer emissions) and budgeting (lower cost) plusses for road building.

In March 2009, the Asphalt Research Consortium (ARC), consisting of the Western Research Institute, Texas A&M University, the University of Nevada-Reno, the University of Wisconsin-Madison and Advanced Asphalt Technologies, met with Manitoba Infrastructure and Transportation (MIT) to discuss research being conducted by the ARC and the desire of MIT to incorporate “green” technologies into its asphalt paving construction. The ARC was working on a five-year research project funded by the Federal Highway Administration (FHWA) with significant emphasis on “green” technologies like higher levels of RAP, warm-mix technologies, and cold-mix technologies.

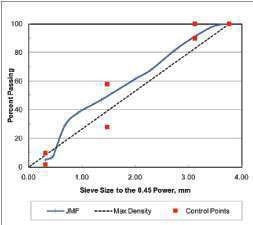

Fig. 1 Gradation of the Manitoba PTH 8 aggregate.

Fig. 1 Gradation of the Manitoba PTH 8 aggregate.Both the ARC and MIT were interested in incorporating higher levels of reclaimed asphalt pavement (RAP) into pavements to reduce the cost of new pavement and to recycle the value and materials from the older pavements. Recycling of asphalt pavement into new pavement is not new, but using higher percentages of RAP in the surface lifts of pavement is not nearly as common. But constructing sections with high RAP content was not the only concern. MIT and the ARC wanted to monitor the performance of pavements to obtain valid data on the value of using d materials.

Designing the Road

In the early discussions, MIT was planning on using RAP on a 28.5-kilometer (about 17-mile section of Provincial Trunk Highway 8 from Gimli to Hnausa. The ARC was interested in using 50-percent RAP in the top two lifts of the pavement and providing asphalt binder and mix testing of the proposed materials prior to construction. MIT was also very interested and enthusiastic to try higher levels of RAP in surface courses and to have additional resources to help test and evaluate the materials. Since the old pavement on the project highway was being completely removed, it was advantageous to be able to use all of the available old pavement in reconstructing the highway. The final plan for the RAP pavement sections included a section with 50-percent RAP, a section with 50-percent RAP and a softer grade of asphalt, a section of 15-percent RAP, and a section of conventional hot-mix, all of which were to be constructed in sequential pavement sections in the same project using the same contractor and the same materials. The plan allows for a direct comparison of the effect of RAP on pavement performance.

The hot-mix plant used on the Manitoba RAP project. The bin on the left was used to add RAP to the mix.

The hot-mix plant used on the Manitoba RAP project. The bin on the left was used to add RAP to the mix.The MIT project personnel conducted mix design testing of the four proposed mixes and provided materials to the ARC members at the University of Nevada-Reno (UNR), the University of Wisconsin-Madison (UWM), and Western Research Institute (WRI). The MIT mix designs adjusted the aggregate gradation to account for the gradation of the RAP at both the 15-percent and 50-percent levels. In some cases where high RAP content is planned, it is recommended that the RAP be fractionated into coarse and fine fractions using the ¼-inch sieve. Because high RAP content paving mixtures are not common in Manitoba, the contractor was not required to fractionate the RAP into coarse and fine fractions.

RAP stockpile used on the Manitoba RAP project.

RAP stockpile used on the Manitoba RAP project.The mix designs used the Marshall mix design method with a target air void of 4-percent, 5.1-percent asphalt content, and 13-percent voids in the mineral aggregate (VMA). The geology of Manitoba, being mostly an ancient lake bed, makes it challenging to economically use substantial quantities of rock. Therefore, most of the aggregate gradations are on the finer side of the maximum density line and manufactured sand is used as a method to attain VMA. A plot of the Manitoba aggregate gradation is shown in Figure 1.

The UNR team and the WRI team also tested and characterized the asphalt cement planned for the project. Manitoba is fortunate to have only one source of asphalt (one crude oil source) for its projects, and the asphalt has historically provided good performance so testing of the asphalt cement before construction was almost certain to represent actual construction. The project asphalt was designed to be a 150/200 pen asphalt from the McAsphalt Industries terminal in Winnipeg. The softer grade planned for one of the 50-percent RAP sections was also supplied by McAsphalt and was a 200/300 pen asphalt. The UNR team performed Superpave binder testing on the two asphalt samples. The 150/200 pen asphalt graded as a PG 58-28 with the continuous grade being a temperature of 136.0° F. and -25.96° F. The 200/300 pen asphalt graded as a PG 52-34 with the continuous grade being 129.38° F. and -29.92° F. In both cases, the low temperature value was controlled by the bending beam stiffness value and not the slope of the creep stiffness value (m-value).

In many other cases, the low temperature grade is determined by the m-value. Research at WRI has shown a correlation between the crystallizable fraction of straight-run asphalt and the low-temperature controlling value with the low crystallizable fraction asphalts having the low-temperature specification limits controlled by the stiffness value. Asphalts that have a higher-crystallizable fraction have the low-temperature specification value controlled by the m-value.

The UWM and UNR teams used the pre-construction materials provided by MIT in the development of a new RAP mortar test to evaluate the properties of the virgin/RAP binder blend without using a solvent extraction. RAP mortar is defined as RAP material that passes the Number 50 sieve and is retained on the Number 100 sieve. The sieved RAP material is mixed with fresh binder at the desired concentration and a beam of material is prepared in a standard bending-beam mold. Using the BBR data from the fresh binder and the data from the BBR beam including RAP, the effect of the RAP on the low-temperature grade can be determined. A similar procedure can be used using the dynamic shear rheometer (DSR) to determine the effect of RAP on the intermediate and high-temperature properties. More information on the ARC testing and research can be found at the ARC website, www.arc.unr.edu.

Construction of the sections commenced in September 2009. The construction consisted of two 50-millimeter lifts of each of the four materials. A 1.3-killometer length of each material was constructed with great attention to ensure that the correct material was placed in both lifts in the correct locations. It was an important requirement of the project to have a substantial length of each material to allow the production equipment to attain a smooth and continuous processing environment for the temperature and production rate. Another aspect of the 1.3-killometer pavement length was to have enough length to plan and establish two 500-foot performance-monitoring sections in each material.

Documenting Construction

During construction, personnel from MIT and WRI were present to document mix-plant conditions, placement location of materials and sampling of paving materials. Another goal of the project was to collect substantial quantities of the construction materials for testing of the as-constructed pavement and also to collect large, but reasonable quantities of construction materials for storage at the FHWA Materials Reference Library. Storing construction materials provides an opportunity to conduct testing on these materials in the future if new performance-related tests are developed. MIT and WRI personnel collected approximately 26,000 pounds of loose mix, 6,000 pounds of aggregate and RAP; and about 250 gallons of asphalt cement.

The UNR team is conducting tests on the plant-produced mixtures for moisture damage, permanent deformation (rutting), fatigue cracking and thermal cracking (transverse cracking). The mixes are tested for moisture damage using the multiple freeze-thaw procedure outlined in AASHTO Method T-283. The permanent deformation testing is evaluated using the repeated load triaxial test in the Asphalt Mixture Performance Tester (AMPT). The fatigue cracking propensity of the mixes is being evaluated using the flexural beam fatigue test, AASHTO T321-07. The thermal cracking properties of the RAP mixes are measured using the Thermal Stress Restrained Specimen Test (TSRST), AASHTO TP10-93.

Results of the testing to date indicate that the four mixes (three containing RAP, one hot mix) will perform adequately. One of the main goals, if not the largest goal, of the project for both the ARC and MIT is to compare the laboratory testing with actual field performance.

Measuring Performance

Following completion of construction, WRI and MIT personnel established two 500-foot performance monitoring sections in each of the three RAP and one hot-mix sections (eight monitoring sections). The sections were established and the initial monitoring used the FHWA Long-Term Pavement Performance (LTPP) guidelines and protocols. MIT personnel conducted Falling Weight Deflectometer (FWD) and Longitudinal profile testing of the sections for baseline data.

Subsequent LTPP protocol distress monitoring will be conducted annually on the 500-foot sections by the ARC. Distress documentation will follow LTPP protocol. Core samples will be obtained annually to examine the physical and mechanical properties of the pavements by the UNR team. The WRI team will use the core samples to assess the extent of aging in the asphalt and the effect of the RAP on aging.

The first annual performance monitoring of the Manitoba RAP sections was conducted in October 2010. As should be expected, all of the sections are performing well and no distress was noted.

Data gathered during the life of this project will help determine the value of using RAP and help the asphalt community learn how to use high levels of RAP in the most effective manner. MIT and the ARC expect this to be a long-term relationship. v