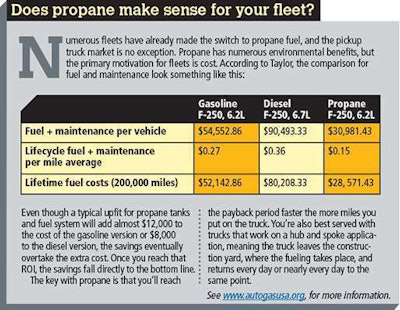

The reason is simple: with the cost of propane running just north of $2 per gasoline gallon equivalent, these trucks make economic sense for a wide variety of applications. (See the sidebar “Does propane make sense for your fleet?” on page 38.)

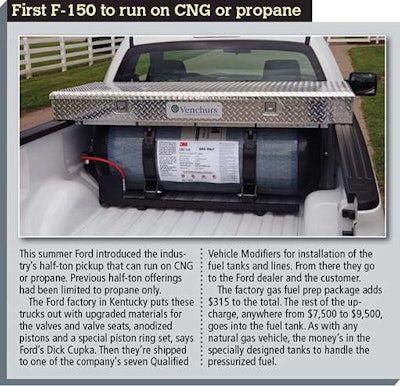

But before you make the leap into the new world of this clean, low-cost fuel, you need to prepare your shop and your technicians. To get the skinny on what this involves we talked with Dick Cupka, product development sustainability manager for commercial vehicles at Ford; Todd Mouw, vice president of sales and marketing at Roush CleanTech; and Michael Taylor, director of autogas business development for the Propane Education & Research Council.

Oil change intervals. Propane is exceptionally clean compared to liquid fossil fuels. Soot is typically the first condemning factor for lube oils in engines burning diesel or gasoline. And since soot is carbon and there’s much less carbon in propane fuels, your oil will stay much cleaner much longer burning propane. That being said, OEMs recommend you stay with the traditional oil change intervals, the same as you have for gas and diesel powered models, at least for now.

“Propane doesn’t break down the additive package in the oil as fast as gasoline,” Mouw says. “More than likely you will eventually see an extended oil change interval for propane. We don’t recommend that, yet. But we have some fleets that are outside their warranty period with the OEM and they’re extending drain intervals to about double what they do with gasoline.”

Should extended drains become authorized by the OEMs in the future, this will help boost the ROI and shorten the payback interval for propane powered engines.

Fuel system

The Roush CleanTech propane fuel system consists of a one-piece billet aluminum fuel rail, fuel injectors, stainless steel lines and tank. In the fuel system the only filter a customer would touch is an inline filter that’s changed every 50,000 miles, Mouw says. The propane remains in a liquid state until it gets to the cylinder, which has alleviated some of the cold start problems associated with vapor technology propane systems from 20 years ago, he says. Since the fuel is liquid, it needs a pump, which resides in the bottom of the fuel tank, and as with a gasoline fuel pump, you could damage it if you perpetually run the truck low on fuel.

Depressurize. As with any pressurized system, gaseous fuel can be dangerous if you are working on the system and fail to bleed off the pressure before removing components.

“There are special safety precautions you take to make sure you are reducing or eliminating pressure on the line or valve before you remove components,” says Cupka. All manufacturers have specific instructions on shutting off the fuel tank and bleeding pressure from the system, so make sure you follow these.

“We send out our technicians to make sure these guys are trained in these procedures before they ever see a vehicle,”Mouw says. “You have to be careful, but the safety risk of working on a propane system at 150 to 200 psi is much lower than working with CNG, which is pressurized at 3,600 psi. Typically you pull the shutoff valves, bleed the pressure off and open up the fuel lines.”

Building codes. The National Fire Protection Association Code for Motor Fuel Dispensing Facilities and Repair Garages, the International Building Code and the National Electric Code detail the requirements for building or modifying a vehicle repair or maintenance facility. These primarily deal with facilities that use liquid fuel (gasoline and diesel).

To make sure you’re up to code for propane you will also need to adhere to the NFPA 58 Liquefied Petroleum Gas Code and the NFPA 30 A Code for Motor Fuel Dispensing Facilities and Repair Garages. Note that these are national codes and standards, that are adopted voluntarily by the states and in many cases the states and some municipalities will have additional requirements.

Flashing and calibration. All cars and trucks today have a “brain” or powertrain control module that’s programmed to make sure the engine, transmission and fuel system work as a harmonious whole. When you take your vehicle to a dealer, if there is a change or update to the software controlling your systems, the dealers will usually overflash the ECM with a new instruction set that includes the improvements. These are typically matched to a VIN number, Cupka says.

Anybody working within the OEM’s system should see and note that you have a vehicle running on propane or other gaseous fuel. But if somebody were to make a make a mistake and flash the wrong calibration, it could cause problems, he says. Check to make sure your dealer or repair shop understands that it is a gaseous- fueled truck anytime you take it in for any kind of work or service. EW