What goes into calculating the owning and operating costs of a compact track loader?

We’ll be delving into that question, but first you should know this will not be a plug-and-play discussion. The variables around each machine purchase are considerable, and the end number can differ significantly from owner to owner. These variables include the machine options you select, the severity of your application, how long you intend to keep the machine, interest rates and local labor and fuel costs.

In the end, what you are looking for is a solid estimate of your CTL O&O costs, one you can use to evaluate what your anticipated hourly costs will be over the life of a machine you’re considering buying.

This process will also give you a baseline number as a machine goes through its life in your fleet and help you evaluate whether it met your expectations. It will also help you hone your process for the next CTL you buy, especially if there were some unexpected factors that significantly affected your anticipated costs.

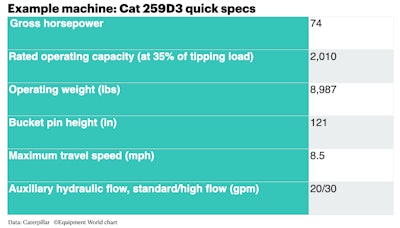

For this discussion, we’ve tapped into the expertise of two Cat product specialists, Kevin Coleman and Theren Peterson. Our sample machine will be a 74-horsepower Cat 259D3, which at 2,010 pounds rated operating capacity is a little over midway on Cat’s CTL size depth chart. For more 259D3 specs, check the chart below.

To help you plug in your own numbers, we’ve added a calculator that you can download here. This calculator is designed to give you a beginning estimate of the O&O costs for the machine you’re considering. To do a deeper dive, we recommend you talk with your dealer.