At the Intermat show in Paris last week, Hamm unveiled its first pneumatic tire roller to feature the Easy Drive operation system, the GRW 280i.

Hamm calls Easy Drive, which is also used in the tandem rollers of Hamm’s DV+ and HD+ series as well as in the single drum compactors of the H series, “intuitive” and “easy to master.”

“It simplifies the operation of complex rollers and enables us to avoid the need for complicated, menu-guided controls”, says Gottfried Beer, head of marketing for Hamm.

What makes the operation system so intuitive is the logical arrangement of a small number of switches in the uncluttered operator’s platform. All Easy Drive rollers have a steering wheel, while drive control is tied to a joystick with clearly visible push-button switches in an ergonomically ideal layout on a multifunction armrest.

Because Hamm has adopted a cross-series approach in the development of the concept, the operating elements for identical functions are now always in the same position on the operator’s platform for all Easy Drive rollers, whether on tandem rollers, compactors or pneumatic tire rollers.

This leads to an increase in efficiency because operators will be able to switch between different Hamm rollers flexibly and without needed to become accustomed to different layouts, the company says.

Increased flexibility for adjusting machine weight

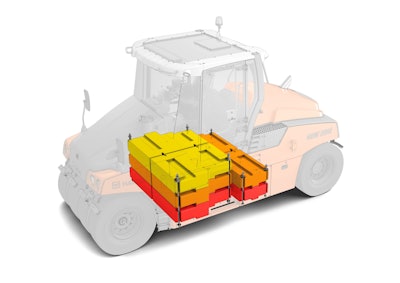

With a new modification to the ballast space between the wheel sets and the open-bottomed, compartmented frame with inserts, it’s now easier to ballast this new roller, Hamm says.

Using a forklift, for example, the prefabricated steel, magnetite or concrete ballast bodies can be inserted or removed. Custom-designed ballast body kits are available, too, or you can fit the roller with your own ballast bodies.

The load remains evenly distributed over both sides because of the way the ballast space is arranged, Hamm says.

Intelligent drive control for top compaction results

The intelligent drive control includes automatic soft raps for even, gentle braking and acceleration, which helps prevent uneven compaction.

The GRW 280i has hydrostatic rear-axle drive, and the driver can set the desired speed using electronic control. A pre-selection wheel on the control panels allows easy setting of the working speed.

To match the high top speed of this machine, a newly designed front steering axle with disc brakes provides braking power and a high left of safety when traveling fast, even with the maximum ballast load. An option is the anti-slip control for optimum traction on uneven ground or on surfaces with varying temperatures, Hamm says.

Wheel suspension innovation helps avoid irregular compaction

Two swingarms, also known as swing forks or pivoted forks, helps to minimize bumps and distribute the load evenly on the wheels, regardless of the ground characteristics.

“Irregular compaction is thus avoided thanks to the even surface pressure,” Hamm says. “A further benefit is that the suspension is designed so as not to intrude into the driver’s field of vision and impair the view of the construction site.”

Unobstructed view at the construction site

One of the special features of the Hamm GRW is the asymmetric frame, which follows the track offset between the front and rear wheel sets.

Hamm describes it as both a “hallmark and a quality benefit, because the design in symmetry with the wheel sets provides a clear view of the outer wheel edges.”

Also included as an option is tire illumination for working at night.

In addition, the compact shape of the GRW 280i, the design of its engine cover and fuel tank, the high seating position, the sliding and swivelling seat plus a spacious cab enhance an unobstructed view in all directions, the company says.

For more information on the world premiere of this machine, click here.