Developed under Cat’s Virtual Site Solutions joint venture with Trimble and launched/unveiled at the Bauma trade show here in Munich on Monday, the next-generation version of VisionLink features a responsive website design. This allows it to provide its full feature set and information layout across PCs and mobile devices.

“The application is the same no matter where you access it,” says John Thomas, director of marketing for Virtual Site Solutions.

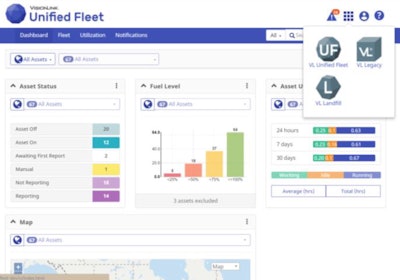

The new VisionLink design loads faster, is less cluttered and displays data in a much easier to digest format, replacing the spreadsheet look of the old site with colorful graphs and charts to provide diagnostics at a glance. It also features infinite scroll which works kind of like your Facebook feed, loading up new data as you scroll down rather than forcing you to click between pages.

The new design also features a customizable dashboard.

“There was some level of customization in the current version of VisionLink and we are stepping that up,” Thomas says. “Customers can actually choose what information they see on the screen along with the order it’s in, the alerts they receive and the type of reports they receive.”

This customizable dashboard, an example of which is seen above, greets customers upon login, giving immediate access to the machine data they want most. The dashboard is composed of widgets that can be edited and reorganized.

To illustrate how useful this customization can be, during a recent press briefing Thomas added a widget to an example dashboard that tracks fuel levels of all active machines in the field. Then he added it again, but this time restricted the machines it tracked to a specific group.

“Let’s say I’ve got this group of hauling assets. I can get advance notice on when to dispatch the fuel guy to that site while the other widget continues tracking all of my other machines,” Thomas says.

The dashboard can even be configured as an auto generated daily report with VisionLink creating a PDF of a user’s dashboard widgets and emailing it out at a certain time each day.

A growing suite

Expanding on that customization, the VisionLink site will be split into a suite of “apps,” each of which are focused on a task or job role. The suite will be accessible via a grid button in the VisionLink navigation bar. Thomas says this refined organization of feature sets will allow customers with different responsibilities within a company to quickly access the data pertinent to their job.

The first of these apps, the rest of which will be built, Thomas says, over the course of the next 12-18 months, is Unified Fleet. This app is tailored for equipment and fleet managers, focusing mainly on hours, miles, location and utilization. The app also allows quick fleet filtering to whittle data down to specific jobsites or machine types.

As its name suggests, the VisionLink Landfill app, is developed for landfill operators and features views to better manage solid waste operations to monitor fill and compaction when using 3D/GPS Trimble CCS900 Compaction Control systems or Cat AccuGrade Compaction Control systems. The app calculates the volume of waste being placed and the compaction densities achieved, Cat says.

And while the overhauled design and customization features make up the majority of this update, the most interesting and maybe most highly anticipated feature—not just of VisionLink but of all telematics dashboards—is the ability to view an entire mixed fleet in one place.

Mixed-fleet diagnostic views

Thomas says the new VisionLink is compatible with version 1.2 of the Association of Equipment Manufacturers/Association of Equipment Management Professionals telematics standard.

“That standard continues to evolve a specific set of data coming from telematics devices that the manufacturers have agreed to share with each other at the customer’s request,” Thomas explains. “So if a customer doesn’t want to go into all the different telematics software (for each brand of machine they own, as is currently required) they can now share their data to something like VisionLink and log into one piece of software to see all of it.”

Demonstrating the view of a mixed fleet, Thomas showed an example fleet of Cat and John Deere equipment listed all together. The machine data can be filtered by manufacturer though Cat can’t guarantee that VisionLink will be able to display all of the same data on third-party equipment as it does on the Cat machines.

“They’ll need to ask that question of their dealers to see what specific data will be shared between manufacturers on specific models. The 1.2 standard is really focused on very basic telematics info: Hours, fuel, etc.,” Thomas says. He explains that when data is sent from a machine, it first heads back to servers belonging to that machine’s manufacturer along with a lot of information considered proprietary. For mixed-fleet monitoring, that proprietary information is filtered out before being sent along to a third-party telematics dashboard.

Data that could give competing manufacturers insights on particular productivity and performance figures may be among data not included when third party OEMs send their machines’ data along to VisionLink because the manufacturers have agreed among each other to not share any data that could be used against each other.

“At the customer’s request, the data collected by the OEM’s machine and telematics device, that is identified by the AEM/AEMP telematics standard, can be shared with the customer or with anyone the customer designates to act on their behalf. This is to enable the customer to access and view data from their mixed fleets in a single software solution,” Thomas explained in a follow-up email to Equipment World. “This solution could be a custom designed software solution, an ERP system, or a system specifically designed to meet the needs of construction customers with mixed fleets, such as VisionLink. When a customer requests to have their mixed fleet data accessed and viewed through our VisionLink software, that mixed fleet data is hosted by Virtual Site Solutions as a third party on the customer’s behalf, it is not stored in any OEM’s databases.”

In addition to enabling customers to view data from other machine manufacturers, the updated VisionLink also allows customers to pull in data from machines outfitted with third-party telematics hardware.

Easing the transition

And for those worried about the possibility of their workflows coming to a halt as they learn the ins and outs of this new design, Cat says it will keep the current version of VisionLink functional online in an app called VisionLink Legacy.

“All of the same features our customers have gotten used to over the last six years will be there,” Thomas says. Those features include several that haven’t quite yet made it into the latest version. “The last thing we want to do is tick off those customers by discontinuing a feature as we move to the next generation.”

The good news is that as customers learn the new design, they’ll be able to hop back and forth between it and the Legacy app with a single sign-on that lets them switch apps by simply switching tabs in their browser.