Bridge Climbing

By Tina Grady Barbaccia

Bridges that were once inaccessible by traditional methods can now be thoroughly inspected by engineers climbing and rappelling down the structures.When the floodgates of a large dam in Folsom, Calif., unexpectedly failed during a routine opening, the U.S. Bureau of Reclamation and the Army Corps of Engineers (COE) – the dam owners – mobilized quickly to inspect the remaining gates for distress. However, the location of the main structural components – perched on the dam spillway about 250 feet above the base of the dam – was hampering the abilities of engineers to access the critical areas.

The only way to quickly address the problem was to rappel down the structure so climb-trained engineers from COE (from across the United States) and the Office of Structure Maintenance and Investigations at the California Department of Transportation (Caltrans) were brought in. For two weeks after the 1995 incident, Caltrans engineers assisted COE with evaluating the remaining dam gates. “Extensive investigations, evaluations and materials testing were completed with a minimum of expense and effort,” explains Stephen Sahs, senior bridge engineer, emergency response and bridge coordinator/ fracture critical technical access coordinator/seismic specialist, for the Office of Structure Maintenance and Investigation at Caltrans.

The use of climbing techniques – i.e. rope access – for bridge inspection has proven to be a valuable tool for the investigating engineer or technician, Sahs adds. “In some cases, climbing is the only effective means to gain access to certain bridge elements,” he says, adding that the techniques have been proven to be “an economical and effective for a variety of routine and specialized bridge inspections.”

Caltrans bridge engineers have historically used heavy industrial rope and rigging techniques to gain access for bridge inspection. The rigging was done by either Caltrans’ Bay toll bridge paint crew or private contractors following the standards of the construction industry.

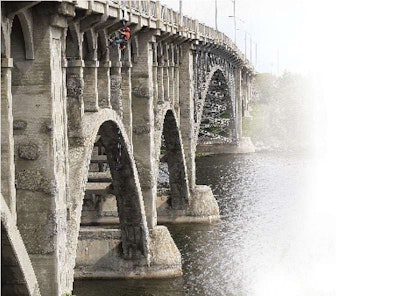

Now, rope access techniques are used in California as an alternative means of gaining access to bridges and structures when other conventional methods cannot be used due to inspection equipment limitations and/or when traffic is greatly impacted. More than 50 bridges in Caltrans’ jurisdiction have been identified as structures where climbing is the only means available to perform structural investigations.

In some situations, climbing is the only effective means to gain access to certain bridge elements.

In some situations, climbing is the only effective means to gain access to certain bridge elements.“The traditional uses of under bridge inspection trucks, life equipment and rigging are economically and practically limited by bridge size, structure type, traffic demands and support costs,” says Sahs, who authored the paper Climbing Techniques for Bridge Inspection, which was presented at the International Bridge Management Conference. (For a downloadable PDF of the paper, go to http://www.betterroads.com/climbing-techniques-for-bridge-inspection/.)

Sahs says that in some cases, bridges have become damaged by earthquakes and have been identified as possessing fatigue prone or fracture critical details that require thorough tactile investigations. However, he says, the structures aren’t able to safely support the loads of heavy personnel lift equipment. “Gaining access to bridge elements to perform these investigations [with traditional bridge inspection methods is]…difficult and costly,” Sahs points out.

Enter bridge inspection via rope access techniques. To address costs and inaccessibility issues, the Caltrans Office of Structure Materials and Office of Structure Maintenance and Investigations evaluated the use of rock climbing and mountaineering techniques as an alternative means of gaining access for bridge inspection. Caltrans’ districts also have a specialized maintenance rock scaling/climbing program as well for steep slope work.

Thanks to a small research grant, a bridge climbing training course was developed throughthrough a local University of California outdoor recreation group. Subsequently, seven engineers and technicians were initially trained. A comprehensive “Code of Safe Practices,” which established training, procedures and equipment required for bridge inspections, followed. The newly trained team then successfully completed a climb investigation on a large, previously inaccessible arch bridge, Sahs says, proving that the techniques for the “Code of Safe Practices” were “safe, economical and effective.”

Within a year, 20 more bridge maintenance engineers were trained, and a formal program was established to organize, schedule, equip and certify engineers and technicians for bridge climbing. Since the program’s deployment, several other offices within Caltrans and the California Department of Water Resources have since adopted the rope access techniques for specialized structural inspection tasks.

“About 15 years ago, we started [climbing] bridges and created our own program,” Sahs points out. A Caltrans engineer, who was also a mountaineer, adapted climbing to bridges. “We put together our own code of practices,” Sahs explains. Meanwhile, the Society of Professional Rope Access Technicians (SPRAT) was formed, along with its now industry-standard certification process, to create industry-wide standards with enforceable rules. “If you’re certified by [SPRAT], you’re pretty much good to go anywhere,” he says. “It means you’ve passed the tests and can perform at a certain level of rope confidence.”

In 2000, the Occupational Safety and Health Administration (OSHA) adopted the Title 8: General Industry Safety Orders Chapter 4, Subchapter 7, Article 1, Section 3207, And Article 4, Section 3270.1 along with Cal-OSHA. The code has spelled out what constitutes a viable Rope Access program. SPRAT was instrumental in the development of these codes.

However, adds Sahs, although OSHA does not require an engineer using rope access for a bridge inspection to be SPRAT-certified, the organization helps regulate that safety practices are adhered to. (Safe Practices for Rope Access Work, go to http://www.betterroads.com/sprat-safe-practices-for-rope-access-work/.)

Regardless of the means of access to a bridge member, every bridge inspector must undergo the two-week course from the National Highway Institutes, Safety Inspection of In-Service Bridges, as a mandate through the National Bridge Inventory and National Bridge Inspection Standards.

“Because of increasing costs and difficulties associated with using traditional inspection equipment, Caltrans bridge maintenance engineers, materials testing engineers and technicians felt it was reasonable to explore alternative means to gain access to bridges,” Sahs says.

A View from the Top

As I step out of the bridge inspection truck, bright yellow lights flashing, cars and semis blazing by at 70 mph, my first thought is for the safety of my crews and how this day will end up. Questions run through my mind: “What will we find on this structure? Is the rope access team ready for another grueling day of physical activity? Is the client happy with our work? Is the weather going to hold out?”

About this time — it never fails — a passenger car will pull up into our shoulder safety zone and ask us for directions to the nearest gas station or inquire what we are doing on the bridge. After explaining to them that they need to exit our safety zone and get on their way — very carefully, I add — the team gets back to the task at hand.

Next, the daily site safety review and coordination meeting is conducted. I inform the teams who will pair with whom, which person is the overall team leader for the pair, and what the team should expect during the course of the day. After answering numerous questions, reviewing the bridge drawings, handing out our field computers and notebooks and reviewing the emergency rescue operation plan, we get to work.

Setting our primary and backup anchors is the first order of business. Extreme care and concentration must be taken to ensure that no issues whatsoever will cause a failure of our rope anchor systems. These systems are literally holding us to the bridge, and to life. Without a solid redundant system that can hold the weight of a pickup truck, our work cannot and will not begin. After checking our anchors and connecting double-locking carabineers to the ends, we begin to deploy the double rope systems. We always use two ropes at a minimum, and in some situations we use four independent ropes, depending on the site’s work positioning needs. One rope acts as the primary means of support and the other is a safety backup. Anchors and ropes are now set, harnesses have been fitted and tightened; the gear we need is checked to make sure it is tied off to our harnesses. Everything must be tied off. None of the cameras, scrapers, rulers, carabineers, slings, markers, headlamps, radios, cell phones, field computers, or notebooks can be allowed to drop into traffic or the river below.

One more double check on my Petzl Rig, which is my main rappelling mechanism, and one good pull on the backup device to ensure it’s working correctly and I’m ready. It is now time to climb over the edge of the bridge rail. I take a deep breath, triple-check my systems with a quick glance, and look down hundreds of feet into the large gorge this structure spans. The wind is really whipping today, I realize, but not enough to call off the inspection for safety.

Our job today is to visually inspect, observe, and document the condition of the main supporting members of this bridge. After rappelling past the lower portion of the bridge rail, the exterior steel stringer comes into view. These beams support the loads from the concrete deck above. The deck sits on stringers, the stringers frame into floorbeams, and the floorbeams frame into verticals of the truss. Other crucial components to evaluate during today’s rope access mission are the members of the top and bottom truss chords, diagonals, bolted or welded connections, and gusset plates. The highly trained and experienced team is here to find areas of corrosion, missing bolts, misalignment, distortion, fatigue damage and anything that looks out of the ordinary. Every square inch of each face of every steel beam is inspected at an arm’s-length distance to get the best viewing angle in which to determine its condition.

Down I go on rappel, looking carefully at the steel around me, foot by foot, every few feet moving my backup device down with me to keep it within arm’s reach. I stop at areas I need to document and photograph. Eventually, 80 feet down, I reach the bottom of this vertical and stand up on the lower chord. Nothing exists below me now but lots of air and the river 300 feet below. As I begin to switch my rope access set up from descent to ascent and prepare to jumar back up the rop I just came down, I think to myself: one done and many more to go over the course of the next week…let’s hope the rest of this inspection goes as smoothly as this first rappel.

Ryan Nataluk, P.E., is a bridge inspection program manager for Stantec. Nataluk is SPRAT level 2 rope access technician.

Not all bridges are created equal

Prior to about 2000, standards did not exist for inspectors accessing a bridge via rope access, points out Ryan Nataluk, P.E., bridge inspection program manager for Stantec. The first time bridges were climbed [for inspection] using ropes , a.k.a. rope access,

Should be as such: …using ropes, a.k.a. rope access, was in the mid-1980s, Nataluk says. was in the mid-1980s, Nataluk says. The process gained more popularity in the 1990s, and since about 2000, it has been in a growth mode. “Prior to 2000, there weren’t really any standards,” he says. “The No. 1 thing in safety is anchors and a double rope system.”

Now with SPRAT, which works with the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), climbing methods and safety practices can be regulated. There are three levels of SPRAT certification. Above level 3 is considered an “evaluator.” Within a rope access team, a level 2 or level 3 candidate undergoes extensive self-rescue training in case of an accident. You go through a lot of rope rescue training, Nataluk points out. “It’s similar to mountaineering type rescue training.”

A minimum of two inspectors must climb together, but a typical rope access inspection team has four to six people training, with a team of four being the most common. “You cannot climb alone,” Nataluk says. “You always work in at least pairs of two.” A typical partnership is a level 2 supervisor and a level 1 inspector that breaks into teams, says Nataluk, who has a SPRAT 2 certification.

Caltrans’ Sahs (also a SPRAT level 2 Technician) adds: “Comprehensive climb training is essential for the safety of personnel as well as for the appropriate selection of techniques and equipment for a particular task.” The complete Caltrans bridge Rope Access training consists of two courses: a comprehensive 32-hour basic course conducted by a qualified instructor and a six-hour practical test and a 32-hour self-belay course followed by a 6 hour test. The curriculum – which is broken down into classroom covering knots, equipment, elementary climbing, rope and mountaineering techniques and safety and rescue and hours of practice applying the techniques on a steel truss bridge followed by the timed practical test.

Climbing, however, is not an efficient method to inspect every bridge. “Some bridges will require traditional methods,” Nataluk says. More so than not, using an under bridge inspection unit – commonly known as a “snooper” on a redundant concrete I-bream structure is more cost efficient. “Where climbing comes in is on steel trusses and arches,” he says.

Nataluk gives examples of steel structures built about 50 to 60 years ago over the Mississippi and Ohio rivers. “They have a lot of lacing and bracing to tie off to so they are much easier to climb,” he says.

During a traditional bridge inspection, traffic control needs to be set up. However, traffic control is not needed in rope access inspection – unless the distance below the structure isn’t great enough. “You might have to block off a lane, but that is rare,” Nataluk says. “When climbing a bridge [to inspect it], you don’t have to use mechanical equipment so you don’t have to use traffic control.”

This, in turn, eliminates the time constraints associated with traffic control. Traditional inspections that require lanes to be blocked off typically have to begin after the morning rush hour and end at 3 p.m. before the afternoon rush hour or must resort to night inspection. “Rope access provides more room to move around the structure,” Sahs says. “In photographs it might look daring or dangerous, but it’s actually safer for the inspector to not be in a traffic control zone.”