One of the City of Denver’s storage facilities for road treatment products

One of the City of Denver’s storage facilities for road treatment productsMunicipalities across the country take myriad approaches to managing snow and ice: Maintenance crews are deployed using several strategies, a variety of road treatment products are used, and technology continues to offer new and innovative options to plan for winter weather.

However, mastering the perfect method to efficiently and effectively manage snow and ice is always challenging regardless of advancements in equipment, products and technologies.

But the City of Denver has found a strategy that works well for it. On average, Denver receives about 60 inches of snow each year, so it requires an efficient and effective snow removal and ice management process.The city’s process employs several key tactics that it says offers tangible benefits for both the city and its residents.

Although salt, sand and chemical de-icers remain an important part of ice and snow control, increasing concerns about the environment and more stringent regulations has made use of alternative products very important, especially because they have less impact on the environment.

Salt and sand alternatives

For more than a decade, Denver has not used salt and sand in its mix of road treatment products. Instead, the city relies on Ice Slicer (an all-natural granular product) and MeltDown Apex (an enhanced liquid de-icer and anti-icer). The city says it made this decision based on two main factors: reduced cost per lane mile and environmental impact.

Pat Kennedy, engineering supervisor with the City of Denver and one of the key people who oversees winter snow operations, says that Ice Slicer has reduced the city’s application rates. “With Ice Slicer, our application rates are about 50 to 150 pounds per lane mile, while with most salts and sands, you are looking at 300 to 400 pounds per lane mile,” Kennedy says. “[That means] we are cutting our application rates in half. ”

Putting a dollar value on this, Kennedy says that using the salt and sand alternative comes to about $7.50 per lane mile. Using a salt and sand mix with a higher application rate — even if the unit price is less –the cost comes to about $10.50 per lane mile, Kennedy says. “So we’re 30 percent lower on cost by using Ice Slicer.” he says.

Cost savings are also realized because the city has lower storage requirements due to the reduced amount of materials required for road treatment. “We run through maybe 15,000 to 20,000 tons of material per year and that’s what our storage is at,” Kennedy says. “We have enough storage to last us a year with our per lane application rate. If we put down a salt and sand mixture, then we would need 50 to 75 percent more storage capacity and we don’t have that available right now. Using salt and sand would also result in having to purchase more material during the winter at an increased rate, sending costs even higher.”

In terms of environmental impact, lower product usage means less of a “footprint” on the environment for the city. Ice Slicer offers additional benefits because its unique mineral composition acts as an environmental buffer decreasing its alkalinity as compared to road salt. Its all-natural composition is also less harmful to roadside vegetation, whereas elevated salt levels in soils can inhibit the ability of vegetation to absorb both water and nutrients, which can slow plant growth and ultimately affect animal habitats. This degradation also affects the ability of these areas to act as buffers to slow the runoff of other contaminants into the watershed.

The salt and sand alternative also works at a lower temperature than road salt, and Kennedy notes that “even a few degrees makes a big difference,” Kennedy noted.

Liquid de-cing for air pollution elimination

In the 1990s, Denver was known for its “brown cloud,” a layer of air pollution that hung over the city. Today, however, efforts have been successful in improving air quality. To help with this, a policy has been enacted that only allows a liquid de-icer (MeltDown Apex) to be used in the downtown area to prevent particles from dry, granular products from entering the air.

“It’s an obvious benefit to the public that we have been able to lessen the ‘brown cloud’ from our use of liquids and a lower application rate of dry materials,” Kennedy said. The city also sweeps up the streets within 72 hours of putting down road treatment products, so the use of liquids in the downtown area helps lower post-treatment clean-up costs.

Advanced technology for advanced planning decisions

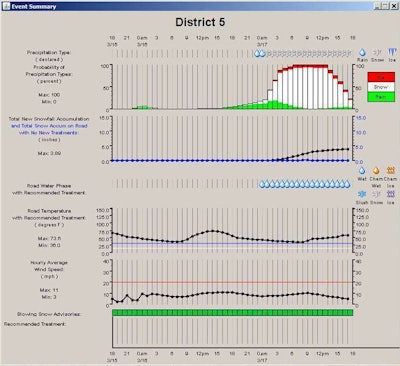

Since the 2005-2006 winter season, Denver has been using a Maintenance Decision Support System (MDSS) to provide it with detailed information used to determine the deployment of maintenance crews. The MDSS utilizes in-ground sensors and several weather forecasting models to provide 48-hour weather forecasts and the effects of the weather on pavements specific to Denver.

“The accuracy of it is way better than national forecasting services because it’s more focused on just the city and not the surrounding area,” Kennedy said. “MDSS goes further that just predicting what the weather will be, it’s predicting what effect the weather will have on the pavement itself. It’s highly focused with a combination of weather forecasts and observations being monitored in the ground and on the ground, and also what’s happening between the pavement and the atmosphere.”

Pictured is a screenshot of the MDSS system that Denver uses for winter maintenance planning

Pictured is a screenshot of the MDSS system that Denver uses for winter maintenance planningMDSS’s advanced technology has helped the city be more efficient in making winter maintenance decisions and planning for incoming storms. “There are several state DOTs using MDSS right now, but as far as cities that are using it, I think Denver is at the forefront of that,” Kennedy said.

A roadmap for the future

Kennedy said that Denver’s current system of snow and ice management has led to an overall improvement in the level of service provided to the general public and better use of the city’s resources, resulting in decreased total maintenance costs. “We don’t see a reason to change things dramatically other than to continue to fine-tune how much product we are applying and when we need to apply it,” Kennedy says. “We’re always looking at how we can maximize our resources and we just want to continue to get better.”

Article and photos contributed by EnviroTech